- #1

tjrk

- 3

- 1

- TL;DR Summary

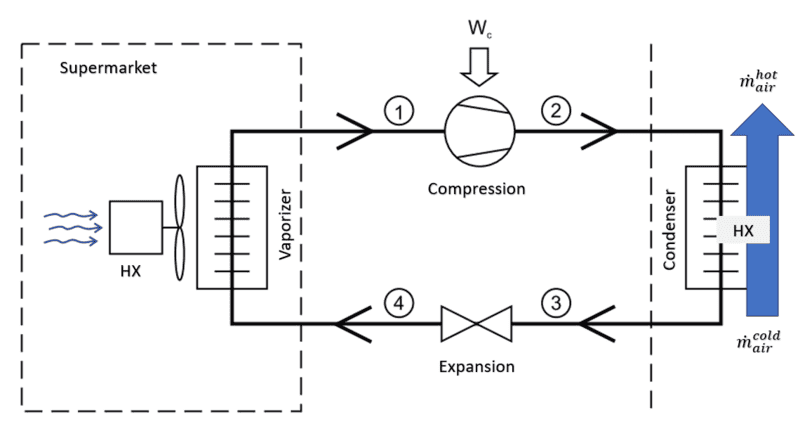

- Cold air mass flow to support supermarkt cooling

An air mass flow of approx. 120 kg/h is available, which can or should be heated up from 0 °C to up to 150 °C. The cooling circuit based on propane R290 is to support the cooling of a supermarket. I have the load curve of the power consumption of the supermarket refrigeration to cool food at a temperature of 4 °C and the air mass flow of the cold air.

How can I conclude from the cold air mass flow to the saved electricity consumption for cooling and is this system reasonable?

Background of this idea is a techno-economic analysis of an energy storage based on compressed air. The usage of cold air could enhance the overall efficiency, the only question is how much energy this could save for cooling the supermarket.

How can I conclude from the cold air mass flow to the saved electricity consumption for cooling and is this system reasonable?

Background of this idea is a techno-economic analysis of an energy storage based on compressed air. The usage of cold air could enhance the overall efficiency, the only question is how much energy this could save for cooling the supermarket.

Last edited by a moderator: