- #1

kfpanda

- 10

- 0

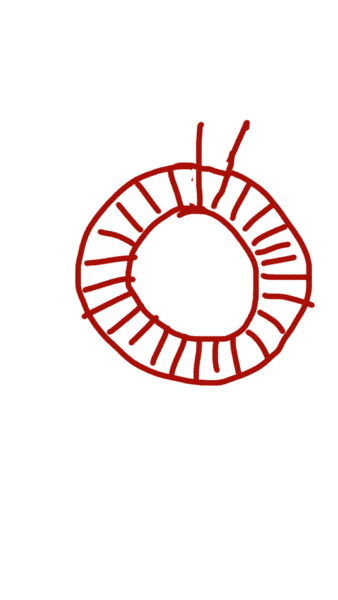

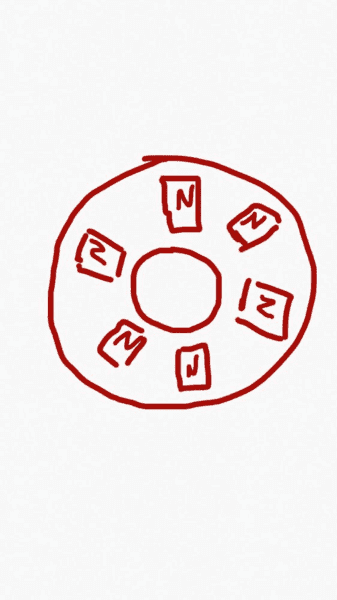

I want to make a dc generator and not sure my design will work. I will wind the coil on a donut shape disk and put 6 rectangular magnets on a disk rotor with North Pole face the coil. Please see attached pictures. Will this design works or have problems? Can I have one continuous coil or I should break it into 6 coils(1 for each magnet)? Also, if the rotor rpm is 3600, what gauge wire I should use for the coil so it won’t burn?

Thanks for your advice.

Thanks for your advice.