Optymista93

- 6

- 2

Hi there,

I would like to use Your expertise in solving one of the challenges I've faced right now, as an intern.

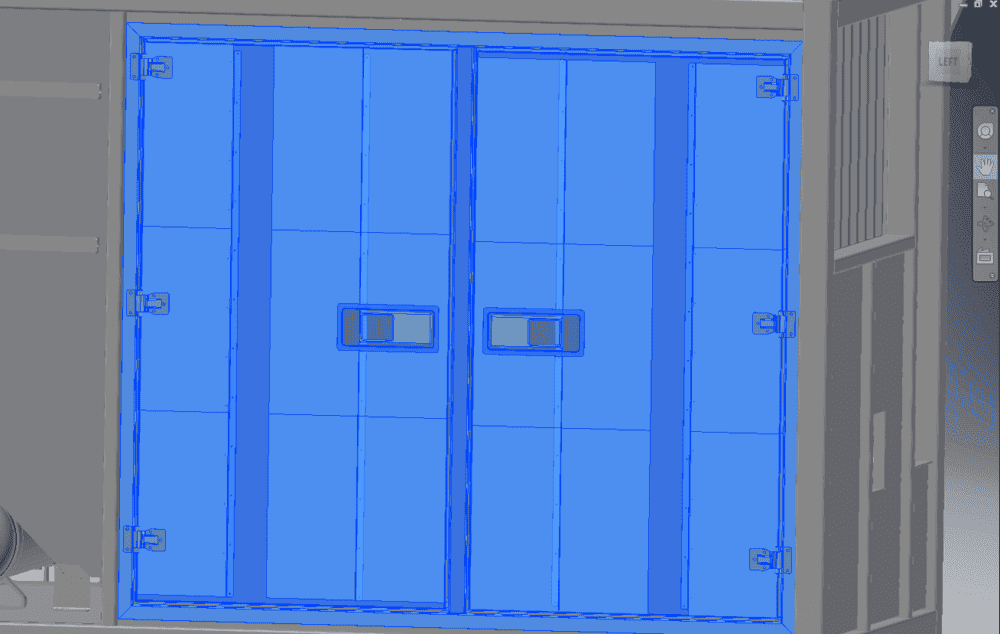

My task is to design steel container doors and its locking system. As it's a light container, locking system should be placed inside of the doors. To visualize, the container and doors looks like this. Among other things, I need to consider "gasket rubbers" (not sure if it's a right English Word for it) around the doors, extream overload caused by the weather & weaves on the ocean etc.

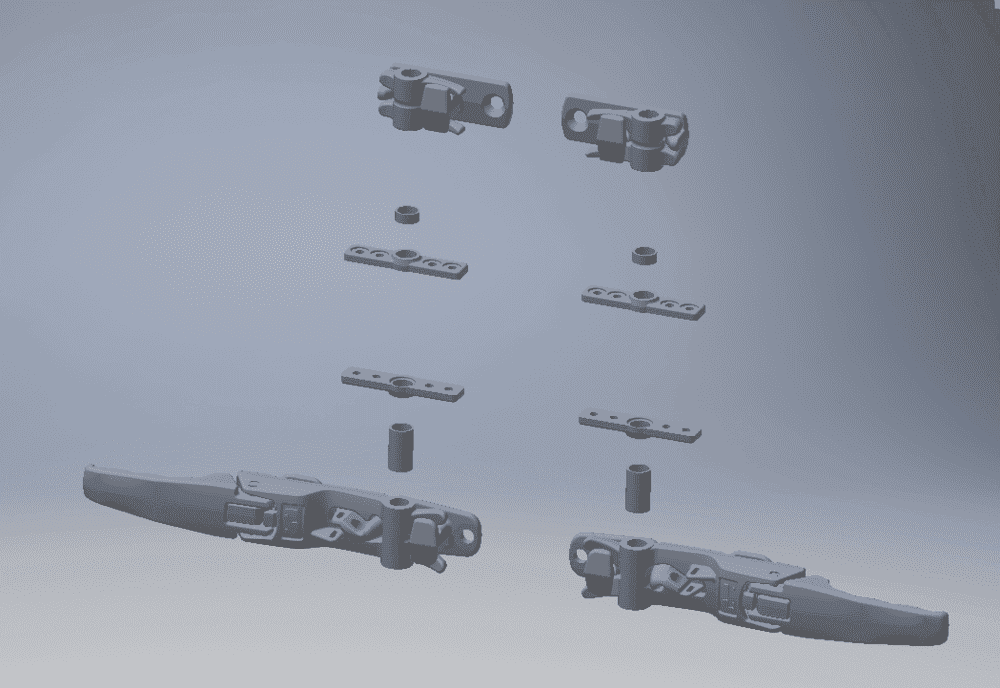

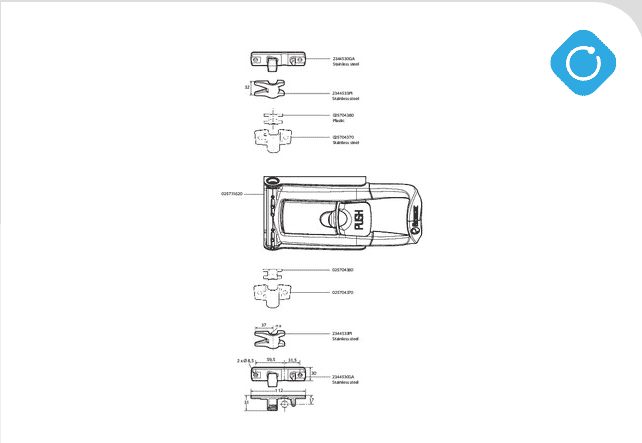

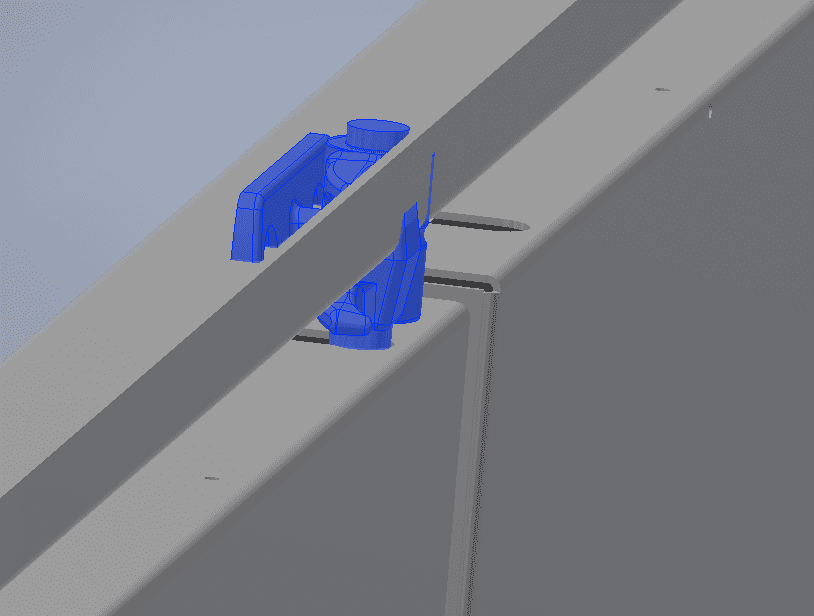

I'll be using locking system similar to one on the images below.

My issue is that I can't figure out how to fasten the lock's fixing to the container and keep the doors sealed.

Lock's fixingJust to visualize a bit more.

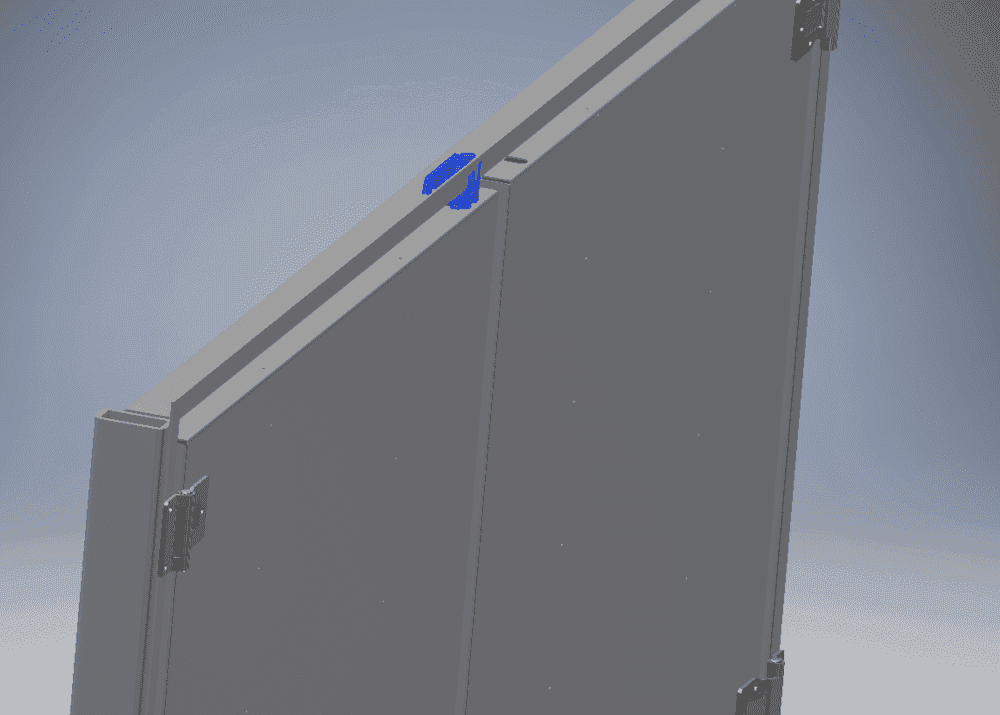

Door frame is adjustable, because we are producing the doors. However, how to keep it sealed ("gasket rubbers") and make it not interfere with the frame?

I would really appreciate all the input.

Thanks in advance,

Dan

I would like to use Your expertise in solving one of the challenges I've faced right now, as an intern.

My task is to design steel container doors and its locking system. As it's a light container, locking system should be placed inside of the doors. To visualize, the container and doors looks like this. Among other things, I need to consider "gasket rubbers" (not sure if it's a right English Word for it) around the doors, extream overload caused by the weather & weaves on the ocean etc.

I'll be using locking system similar to one on the images below.

My issue is that I can't figure out how to fasten the lock's fixing to the container and keep the doors sealed.

Lock's fixingJust to visualize a bit more.

Door frame is adjustable, because we are producing the doors. However, how to keep it sealed ("gasket rubbers") and make it not interfere with the frame?

I would really appreciate all the input.

Thanks in advance,

Dan