- #1

Saints-94

- 63

- 1

I am unsure whether I am posting in the right place, but was hoping someone could help me out.

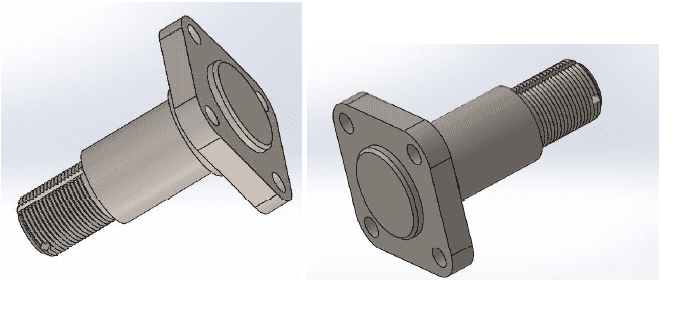

I was wondering if anyone knows the shape of the material at the beginning of the manufacturing process of a stub axle, and how the shape will vary depending on the quantity of products being made (eg. one off, small batch and mass production). Only looking for basic ideas, nothing too in-depth.

See image of stub axle below.

I was wondering if anyone knows the shape of the material at the beginning of the manufacturing process of a stub axle, and how the shape will vary depending on the quantity of products being made (eg. one off, small batch and mass production). Only looking for basic ideas, nothing too in-depth.

See image of stub axle below.