- #1

LeoYorkshire

- 1

- 0

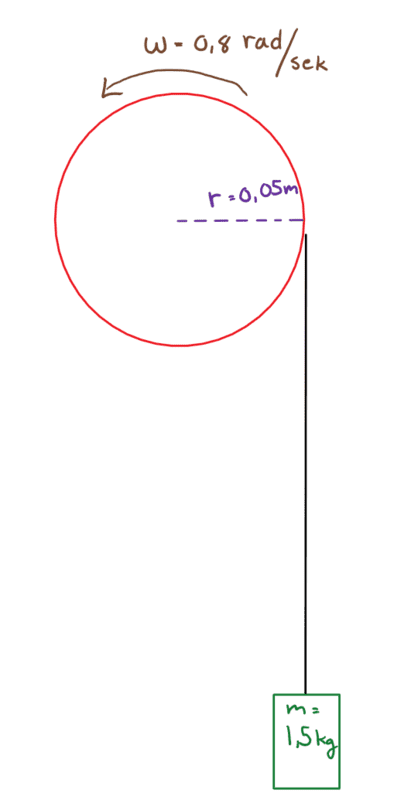

I have a servo motor which rotates 180 degrees. I want to calculate torque of the motor. To calculate the torque I'm thinking of lifting a load of a known value, with a known angular velocity. But I am struggling to find/calculate the torque based on these values. Does anyone know how to do this based on these known values?