- #1

mishima

- 565

- 35

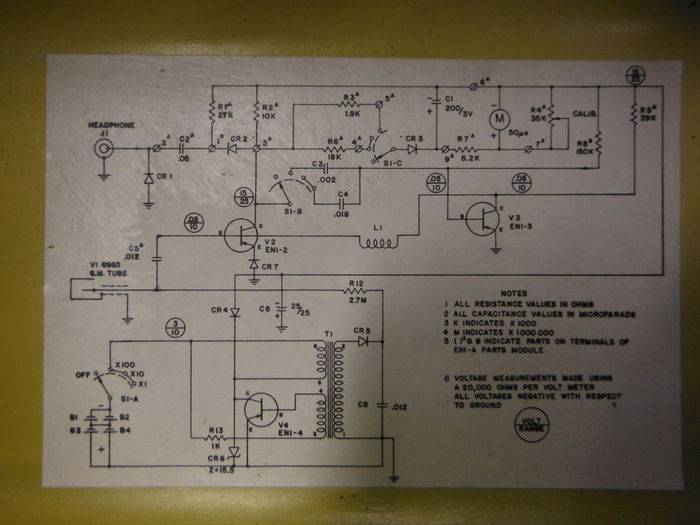

My class was recently donated an old but perfectly functioning Geiger counter. It was the type that came with a mono-speaker which made audible clicks when decay events were detected. It was left on in the cabinets for multiple days, and now there is a steady tone coming through the speaker and the reading on the meter is maximum on all 3 scales. I am wondering if there is any part I could check/test/replace to get this working again, I have little electronics knowledge in general. Schematic and other pictures below.