- #1

redux

- 3

- 0

Hey everyone,

I am an energy modeling engineer, and I would like to ask a question regarding a project I am working on.

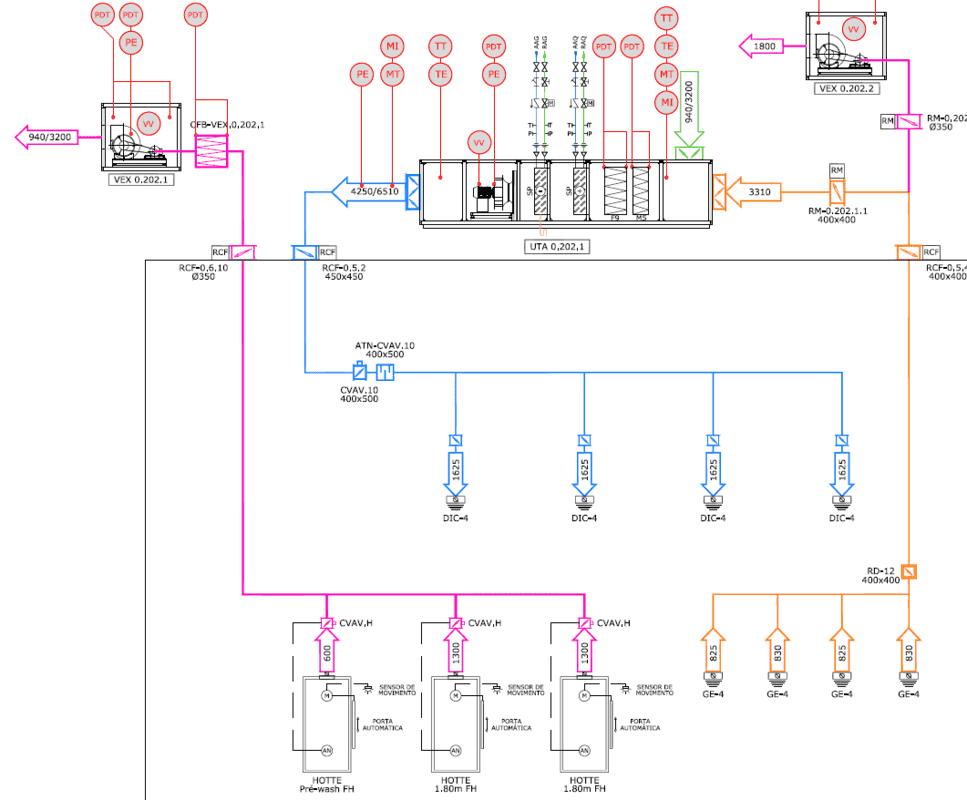

In the attached instrumentation diagram (and I also found this on AHU specification tables), what does it mean to have "air flow1/air flow2" (see figure). I deduce it is the "min airflow value/max airflow value", but I would like to be sure about this. Concerning colors, orange is return air, green is outdoor/fresh air supply, blue is primary air and pink is exhaust air.

Thank you all in advance for your time.

I am an energy modeling engineer, and I would like to ask a question regarding a project I am working on.

In the attached instrumentation diagram (and I also found this on AHU specification tables), what does it mean to have "air flow1/air flow2" (see figure). I deduce it is the "min airflow value/max airflow value", but I would like to be sure about this. Concerning colors, orange is return air, green is outdoor/fresh air supply, blue is primary air and pink is exhaust air.

Thank you all in advance for your time.