- #1

Chrono G. Xay

- 92

- 3

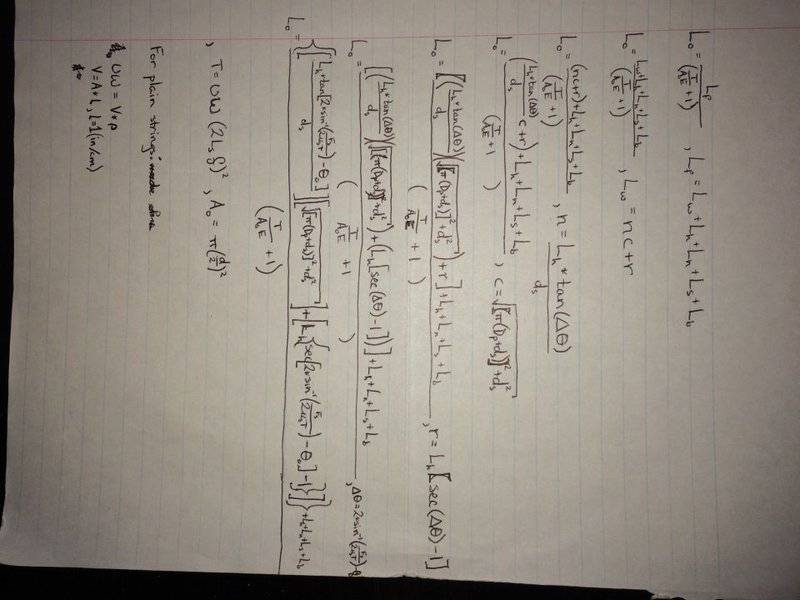

I have put together an equation whose purpose is:

With a desired 'magnitude of static friction' ( μ_s ), 'fundamental frequency' ( f ), and 'tension' ( T ),

initial conditions such as 'string breakover angle' ( Θ_0 ), 'nut-tuner distance' ( L_{h,0} ), and 'string diameter' ( d ),

and, finally, constants 'tuner diameter' ( D ), 'nut thickness' ( L_n ), 'nut-saddle distance' ( L_s ), 'saddle-bridge distance' ( L_b ), 'elastic modulus' ( E ), and 'Poisson's Ratio' ( ν ),

What 'initial length of string' ( L_0 ) is required?

I have already written my work out, and was hoping there'd be someone among the members of PF who wouldn't mind helping to check it with me.

Please keep in mind that I am an undergraduate pursuing a degree in Music Education, studying percussion, and have a great passion for Physics and Math, applying what I learn to further accelerate my comprehension and make the execution of a piece of music that much more fluid and efficient.

(My apologies about the picture- I tried a few times to get it to display right side up, but it wouldn't work for me...)

With a desired 'magnitude of static friction' ( μ_s ), 'fundamental frequency' ( f ), and 'tension' ( T ),

initial conditions such as 'string breakover angle' ( Θ_0 ), 'nut-tuner distance' ( L_{h,0} ), and 'string diameter' ( d ),

and, finally, constants 'tuner diameter' ( D ), 'nut thickness' ( L_n ), 'nut-saddle distance' ( L_s ), 'saddle-bridge distance' ( L_b ), 'elastic modulus' ( E ), and 'Poisson's Ratio' ( ν ),

What 'initial length of string' ( L_0 ) is required?

I have already written my work out, and was hoping there'd be someone among the members of PF who wouldn't mind helping to check it with me.

Please keep in mind that I am an undergraduate pursuing a degree in Music Education, studying percussion, and have a great passion for Physics and Math, applying what I learn to further accelerate my comprehension and make the execution of a piece of music that much more fluid and efficient.

(My apologies about the picture- I tried a few times to get it to display right side up, but it wouldn't work for me...)

Last edited: