- #1

Secan

- 141

- 11

I recently came across a Diaphragm flow switch whose operation many engineers are not familiar with.

First. Supposedly in a normal pressure switch. The pressure will be a maximum when there's no flow, precisely because at zero flow there is no pressure drop anywhere in the system, so the pressure here will be full mains pressure. When the shower-head is on and there's flow, the pressure here will drop.

But in the diaphragm flow switch. It's the opposite. What is in the design in the diaphragm flow switch such that when there is no flow (pressure maximum), pressure won't push the pin. The pin will only extend when there is flow. Let's get back to basic first.

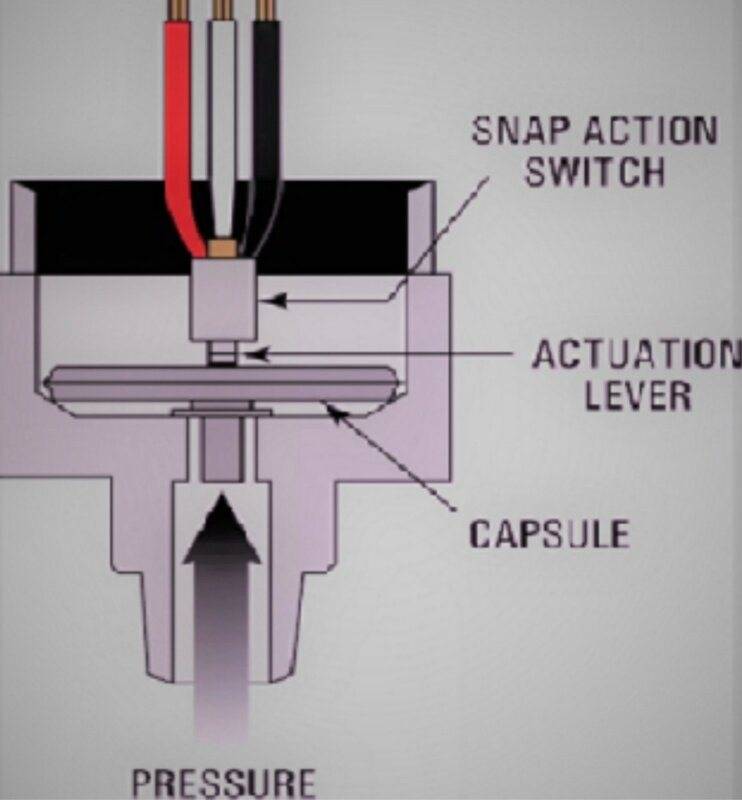

This is the schematic of a pressure switch.

What would happen if the inlet tube is made narrow? Would the pressure still the same given the source has the same pressure? Or would the pressure in the inlet be lesser?

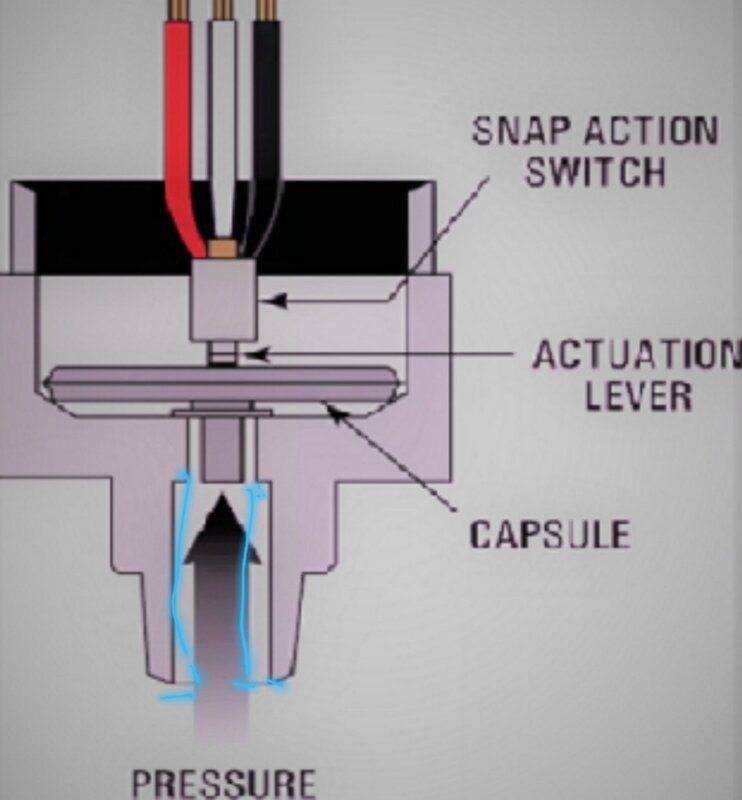

Now supposed you create another hole at the right side of it or an outlet causing a water flow.

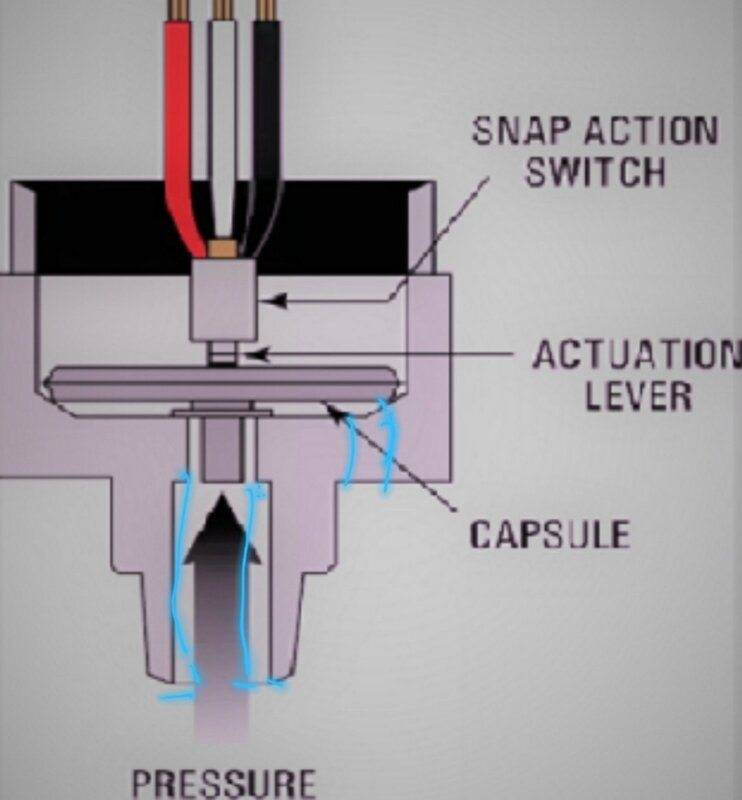

What will happen? The piston will move if there is water flow. But if the 2nd hole or outlet is blocked. Will the piston still move from the perhaps poorer pressure?

In an actual device I encountered. The diaphragm no longer move if there is no water flow. Even if the pressure of the source is the same. Somehow it converts pressure right at that junction into velocity via the Bernoulli principle? i haven't seen this explained elsewhere and just want to confirm.

I want to understand the theoretical side of it.

To illustrate the above. In the following youtube video you can see the pin of the flow switch diaphragm extended when the faucet is flowing (the valve is after the flow or pressure switch) and pin returns when faucet is closed (but pressure maximum since there is supposedly no pressure drop).

First. Supposedly in a normal pressure switch. The pressure will be a maximum when there's no flow, precisely because at zero flow there is no pressure drop anywhere in the system, so the pressure here will be full mains pressure. When the shower-head is on and there's flow, the pressure here will drop.

But in the diaphragm flow switch. It's the opposite. What is in the design in the diaphragm flow switch such that when there is no flow (pressure maximum), pressure won't push the pin. The pin will only extend when there is flow. Let's get back to basic first.

This is the schematic of a pressure switch.

What would happen if the inlet tube is made narrow? Would the pressure still the same given the source has the same pressure? Or would the pressure in the inlet be lesser?

Now supposed you create another hole at the right side of it or an outlet causing a water flow.

What will happen? The piston will move if there is water flow. But if the 2nd hole or outlet is blocked. Will the piston still move from the perhaps poorer pressure?

In an actual device I encountered. The diaphragm no longer move if there is no water flow. Even if the pressure of the source is the same. Somehow it converts pressure right at that junction into velocity via the Bernoulli principle? i haven't seen this explained elsewhere and just want to confirm.

I want to understand the theoretical side of it.

To illustrate the above. In the following youtube video you can see the pin of the flow switch diaphragm extended when the faucet is flowing (the valve is after the flow or pressure switch) and pin returns when faucet is closed (but pressure maximum since there is supposedly no pressure drop).

Attachments

Last edited: