- #1

pete

- 72

- 5

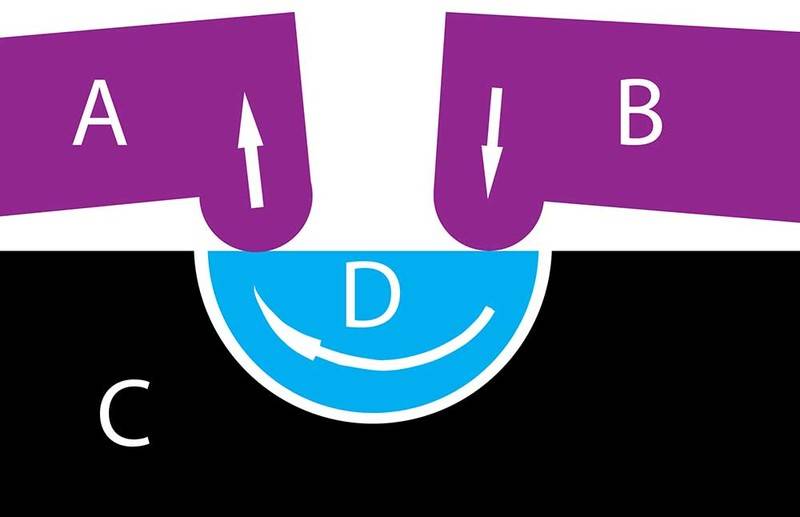

Hi, I’m looking for some advice on materials. In the picture A, B and C are stainless steel. Pressure is applied at B rotating D in the socket and raising A. D needs to be as strong as possible to resist the load but I’m concerned about D rubbing against C as there is no lubrication. I can't change A, B and C and need D to be non corrosive, stainless steel is going to course galling so was considering a plastic like Tufnol, or maybe some kind of ceramic? Any advice?