- #1

MayZ91

- 23

- 0

Hello all,

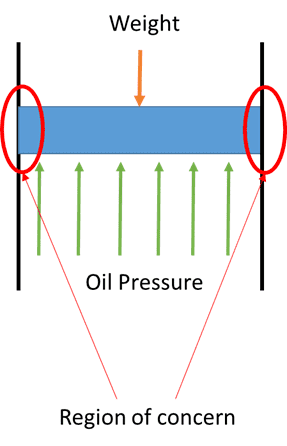

I am working on a few test scripts to test the life of a hydraulic cylinder. (It is a mechanically operated cylinder and has a positive displacement)

The testing will involve thousands of continuous pump and retraction operations, due to which the temperature of the piston seal and the oil will rise.

I need to provide necessary idle time in between the cycles to avoid any failure of the piston seal.

What I have considered so far is the friction pressure on the seal due to its compression (by installation) and friction pressure to the fluid pressure on the seal. From which I was able to arrive at the heat generated per second. However, the friction factors were taken from the supplier catalogue to arrive at these values.

I need to account the heat generated due to work done on the oil and the influence of the number of cycles and time taken to perform these cycles. To build these equations I need to make some assumptions like the cylinder walls do not participate in heat transfer and also there is no loss in heat while the oil while it is pumped (the entire system is a closed loop hydraulic system).

I need to build the equations and determine the idle time that needs to be provided in between the cycles.

I may have not explained here very well, but if anyone is interested to help, I can provide better details.

I have attached the excel sheet to the point I have attempted so far. Not sure if i have taken the right approach and moreover I was not able to include the effect of cycles.

In the excel sheet, the ones in the boundary are seal details and need not be worried about.

I am working on a few test scripts to test the life of a hydraulic cylinder. (It is a mechanically operated cylinder and has a positive displacement)

The testing will involve thousands of continuous pump and retraction operations, due to which the temperature of the piston seal and the oil will rise.

I need to provide necessary idle time in between the cycles to avoid any failure of the piston seal.

What I have considered so far is the friction pressure on the seal due to its compression (by installation) and friction pressure to the fluid pressure on the seal. From which I was able to arrive at the heat generated per second. However, the friction factors were taken from the supplier catalogue to arrive at these values.

I need to account the heat generated due to work done on the oil and the influence of the number of cycles and time taken to perform these cycles. To build these equations I need to make some assumptions like the cylinder walls do not participate in heat transfer and also there is no loss in heat while the oil while it is pumped (the entire system is a closed loop hydraulic system).

I need to build the equations and determine the idle time that needs to be provided in between the cycles.

I may have not explained here very well, but if anyone is interested to help, I can provide better details.

I have attached the excel sheet to the point I have attempted so far. Not sure if i have taken the right approach and moreover I was not able to include the effect of cycles.

In the excel sheet, the ones in the boundary are seal details and need not be worried about.

Attachments

Last edited: