- #1

happytolearn

- 10

- 0

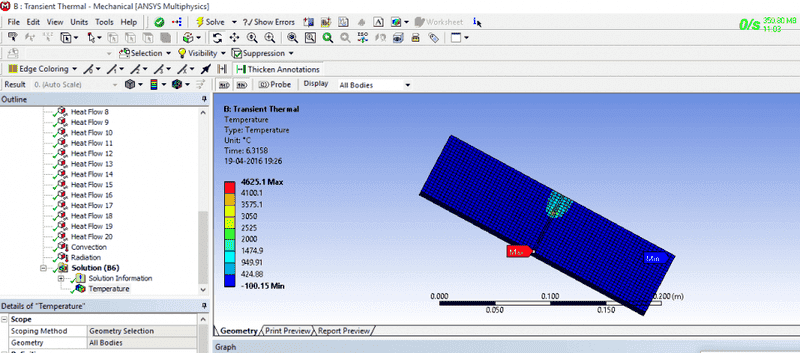

I want to do a transient thermal analysis in butt welded joint.The heat flow I have given 3200 watt(Q = efficiency x current x voltage = 0.8 x 160 amp x 25 volt)to the welding zone, given 20 load step(as welding is completed in 20 sec),convection co-efficient = 11.14, emissivity = .4 and applied both boundary condition convection and radiation on every surface except welding zone. But after solving the minimum temperature of the plate is coming in negative.Can anybody tell me what i am missing?