- #1

Robbwal199

- 22

- 4

- TL;DR Summary

- Looking for a way to manipulate one end fitting of a turnbuckle to hold tension but be able to release all tension on demand.

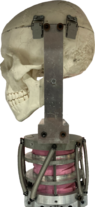

I'm looking to build an adjustable mechanism for a concussion model rig. The premise is that it must be able to tilt the skull, and release the tilt at the moment of impact to not affect how the head whiplashes.

As you can see in Picture 1, I originally designed two platforms to fit onto the model, connected to one another by a mini ratchet strap.

The idea as shown in Picture 2, is that the model could pre-set to an angle, where it accelerates down a track using a pneumatic actuator and the force of the sudden stop at the end of the track would blow the bottom hooks off their anchor point. This would release all the tension in the straps, meaning the skull could whiplash freely mimicking a concussion.

However, I was suggested to use mini turnbuckles (open end full length ~ 250 mm, can be any end fittings) as opposed to ratchet straps, and to also change the mechanism of releasing the bottom attachment due to likely low reliability of release.

So this leaves me with a question: What is the best way of manipulating the bottom fitting of a turnbuckle to tilt the skull, but release at impact?

Any suggestions would be much appreciated.

As you can see in Picture 1, I originally designed two platforms to fit onto the model, connected to one another by a mini ratchet strap.

The idea as shown in Picture 2, is that the model could pre-set to an angle, where it accelerates down a track using a pneumatic actuator and the force of the sudden stop at the end of the track would blow the bottom hooks off their anchor point. This would release all the tension in the straps, meaning the skull could whiplash freely mimicking a concussion.

However, I was suggested to use mini turnbuckles (open end full length ~ 250 mm, can be any end fittings) as opposed to ratchet straps, and to also change the mechanism of releasing the bottom attachment due to likely low reliability of release.

So this leaves me with a question: What is the best way of manipulating the bottom fitting of a turnbuckle to tilt the skull, but release at impact?

Any suggestions would be much appreciated.