- #1

mastermechanic

- 108

- 15

Hello everyone,

I have been trying to find a relatively accurate pressure drop correlation for horizontal flow of air-oil mixture. I have been testing 7 correlation in my test points however I am still hesitated to select the appropriate one based on the results.

System Props:

* D_pipe: 17.63 mm

* Liquid density: 887 kg/m3

* Total Mass Flux (G): 150-300 kg/m2.s

* Gas density: 0.08-1.4 kg/m3

* T_mix: 423 K

* Mass quality (x) is very low: x<< 0.1 (However, due to low air density void fraction is high)

* Superficial reynolds # (Liquid-Gas): Mostly Laminar - Laminar or Turbulent - Laminar

* Flow pattern: Mostly Slug

* Tested Correlations:

1-) Lockhart - Martinelli

2-) Homogenous Flow w/ Blasius friction

3-) Homogenous Flow w/ Churchill friction

4-) Friedel

5- ) Chisholm's two-phase friction multiplier

6-) Müller-Steinhagen & Heck

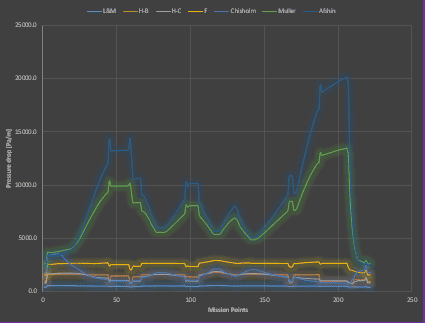

7-) Afshin Ghajar's modification of Müller's correlationPROBLEM: I have tested these correlation through my test points but as you can see in the graph below there is a huge discrepancy between (1-2-3-4-5) and (6-7). The reason behind it is because first five correlations are based on homogenous flow (HFM) assumption however my test range is mostly slug flow. Müller and Afshin correlations are claimed to be accurate in this range but the results also seem too much to me.

* I didn't quite capture why the increase and decrease trends of HFM and (6-7) are inverse at some regions.

* Although my test range has lost of parameters that all change throughout the mission points, the lockhart-martinelli nearly didn't change at all. (L-M method is usually suggested for G<100 maybe thats the reason)

* The pipeline is in fact has some bends and slight inclinations at some points so I would not expect any laminar behavior in contrast to what Re numbers tell us.

Overall, although I am sure of the flow pattern and Muller's correlation is claimed to be most accurate over the entire flow patterns, the large difference and high pressure drop made me suspicious since all other correlations (although they're HFM) are laid well below. I have been thinking if I am doing wrong, if I can model the flow via HFM)

I am waiting for your valuable comments and help to select appropriate correlation.

Thanks in advance,

I have been trying to find a relatively accurate pressure drop correlation for horizontal flow of air-oil mixture. I have been testing 7 correlation in my test points however I am still hesitated to select the appropriate one based on the results.

System Props:

* D_pipe: 17.63 mm

* Liquid density: 887 kg/m3

* Total Mass Flux (G): 150-300 kg/m2.s

* Gas density: 0.08-1.4 kg/m3

* T_mix: 423 K

* Mass quality (x) is very low: x<< 0.1 (However, due to low air density void fraction is high)

* Superficial reynolds # (Liquid-Gas): Mostly Laminar - Laminar or Turbulent - Laminar

* Flow pattern: Mostly Slug

* Tested Correlations:

1-) Lockhart - Martinelli

2-) Homogenous Flow w/ Blasius friction

3-) Homogenous Flow w/ Churchill friction

4-) Friedel

5- ) Chisholm's two-phase friction multiplier

6-) Müller-Steinhagen & Heck

7-) Afshin Ghajar's modification of Müller's correlationPROBLEM: I have tested these correlation through my test points but as you can see in the graph below there is a huge discrepancy between (1-2-3-4-5) and (6-7). The reason behind it is because first five correlations are based on homogenous flow (HFM) assumption however my test range is mostly slug flow. Müller and Afshin correlations are claimed to be accurate in this range but the results also seem too much to me.

* I didn't quite capture why the increase and decrease trends of HFM and (6-7) are inverse at some regions.

* Although my test range has lost of parameters that all change throughout the mission points, the lockhart-martinelli nearly didn't change at all. (L-M method is usually suggested for G<100 maybe thats the reason)

* The pipeline is in fact has some bends and slight inclinations at some points so I would not expect any laminar behavior in contrast to what Re numbers tell us.

Overall, although I am sure of the flow pattern and Muller's correlation is claimed to be most accurate over the entire flow patterns, the large difference and high pressure drop made me suspicious since all other correlations (although they're HFM) are laid well below. I have been thinking if I am doing wrong, if I can model the flow via HFM)

I am waiting for your valuable comments and help to select appropriate correlation.

Thanks in advance,