- #1

Guineafowl

- 762

- 366

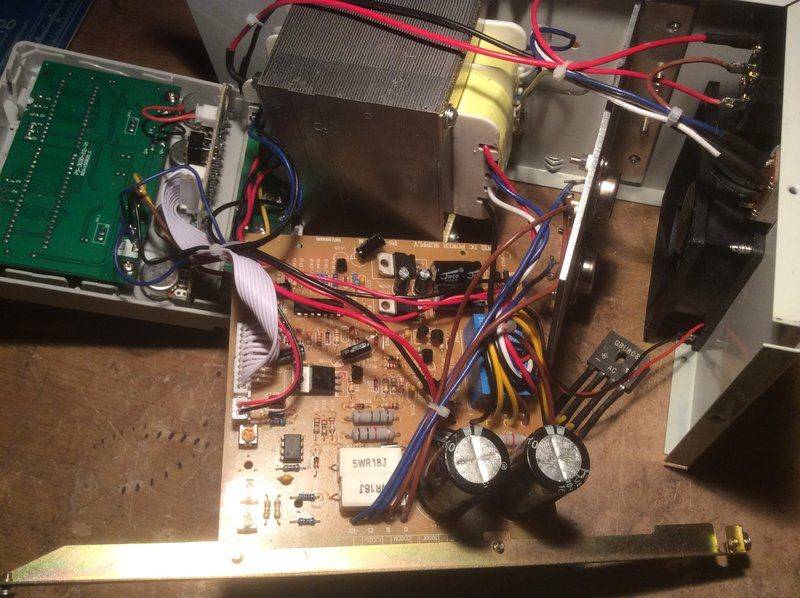

Lavolta BPS 305 0-30V and 0-5A.

I was showing a young lad how you can energise a car ignition coil and get a spark on the output, and that this effect can be improved by adding a cap in parallel which forms a crude LC oscillator etc when the unit died. Silly, I know, but we got a bit carried away. At least he learned something.

The unit powers on, fan runs, but the display reads 0.00V and 0.00A (correct readings) and the current limit light is on.

I realize that troubleshooting a board remotely and from a picture is not feasible, but is there a general layout common to these units that might point me in the right direction?

The fault was most likely caused by a transient from the coil primary, or just simple, repeated overcurrent. This might point me to an IC, such as the LM324 at the top, or the 0P07CP precision op amp on the left. The voltage regulators are working (7815 and 7915).

The large caps are being charged to 20V, but that is not getting thorugh to the output as the series pass 3055s are 'off'.

Any help would be much appeciated.

I was showing a young lad how you can energise a car ignition coil and get a spark on the output, and that this effect can be improved by adding a cap in parallel which forms a crude LC oscillator etc when the unit died. Silly, I know, but we got a bit carried away. At least he learned something.

The unit powers on, fan runs, but the display reads 0.00V and 0.00A (correct readings) and the current limit light is on.

I realize that troubleshooting a board remotely and from a picture is not feasible, but is there a general layout common to these units that might point me in the right direction?

The fault was most likely caused by a transient from the coil primary, or just simple, repeated overcurrent. This might point me to an IC, such as the LM324 at the top, or the 0P07CP precision op amp on the left. The voltage regulators are working (7815 and 7915).

The large caps are being charged to 20V, but that is not getting thorugh to the output as the series pass 3055s are 'off'.

Any help would be much appeciated.