- #1

- 2,116

- 2,691

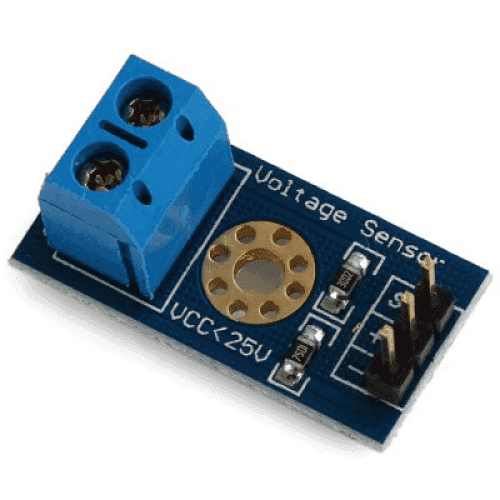

While searching for something else, I stumbled upon this https://robu.in/product/voltage-sensor-module/. It is idiotic to buy something like this, because a voltage divider doesn't cost more than a few cents. But what is the metallic circular component in the middle of the sensor? Some kind of heat shield?