- #1

RamSST

- 1

- 0

Hi. New here. I'm not necessarily a newb at wiring I've used solder before and have wired up other simple wiring diagrams. I'm hoping someone can help me with a task I'm looking at doing. I'd like to wire up a set of LED taillights. 48 red led's in the brake circuit and about 24 in the turn signal circuit. The brake light will require a SPDT relay to switch from being illuminated and braking. I have a diagram but have no idea what kind of resistor values I will need. It's a 12V system. Any help is much appreciated

These are the specs on the red LED's I have:

Specifications:

Material: InGaN

Emitting Colour: Red

Lens Type: Water clear

Reverse Voltage: 5.0 V

DC Forward Voltage: Typical: 1.9 V Max: 2.3 V

Wave Length: 625-635nm

Luminous Intensity: Typ: 15,000 mcd

DC Forward Current: 20mA

Viewing Angle: 20±5degree

Lead Soldering Temp: 260oC for 5 seconds

Intensely Bright

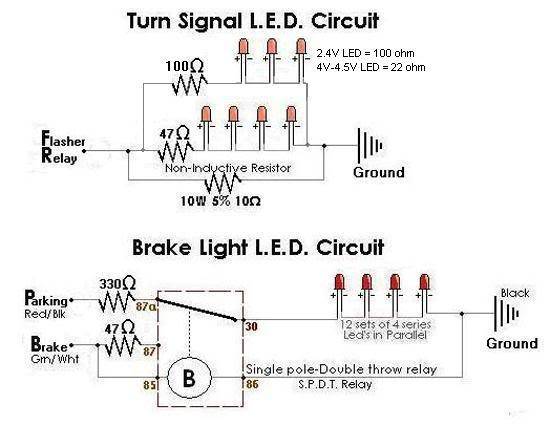

This is the wiring diagram I intend to use:

These are the specs on the red LED's I have:

Specifications:

Material: InGaN

Emitting Colour: Red

Lens Type: Water clear

Reverse Voltage: 5.0 V

DC Forward Voltage: Typical: 1.9 V Max: 2.3 V

Wave Length: 625-635nm

Luminous Intensity: Typ: 15,000 mcd

DC Forward Current: 20mA

Viewing Angle: 20±5degree

Lead Soldering Temp: 260oC for 5 seconds

Intensely Bright

This is the wiring diagram I intend to use: