tirupoti

- 1

- 0

Hi,

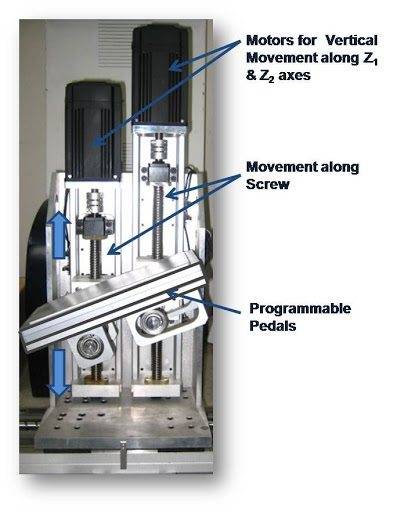

I am using Sensored BLDC motors for some robotic movements. I am driving my motors using motor drivers. I am using ball screw mechanism for lifting a pedal up and down. On the pedal, there will be always a very high load, placed on it.

Now, my motor can lift up the pedal with my desired speed accurately but while going downward, the pedal just goes down freely overcoming the output speed of the motor.

In summery I would like to say, when the motors are on downward rotation, they can’t hold the weight of the load and fail to conform to the desired downward velocity; instead they just let the pedal goes down freely until it reaches the lower threshold.

If you have any questions please let me know

thanks in advance

I am using Sensored BLDC motors for some robotic movements. I am driving my motors using motor drivers. I am using ball screw mechanism for lifting a pedal up and down. On the pedal, there will be always a very high load, placed on it.

Now, my motor can lift up the pedal with my desired speed accurately but while going downward, the pedal just goes down freely overcoming the output speed of the motor.

In summery I would like to say, when the motors are on downward rotation, they can’t hold the weight of the load and fail to conform to the desired downward velocity; instead they just let the pedal goes down freely until it reaches the lower threshold.

If you have any questions please let me know

thanks in advance