- #1

Vatech

- 54

- 7

- TL;DR Summary

- I have a 3 Phase low voltage BLDC but i have a problem of driving it using a Nucleo microcontroller combined with a extension board

Hello Community,

i have BLDC motor with General parameters are 3 Phase motor with 4 Poles, 36V, 7.3A rated current, 4000RPM rated speed.

you can check datasheet on link below

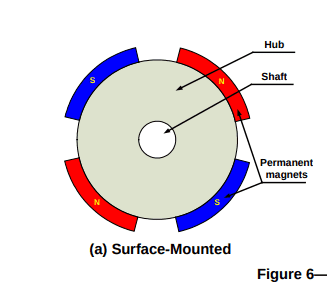

The first question is how many Pair of Poles does this motor have? 2 or 4?

For example the motor bellow

https://www.omc-stepperonline.com/download/57BLR110-36-01.pdf

//For those who want to get depper into the problem :

I am using a Nucleo-F401RE combined with the extension board X-NUCLEO-IHM08M1 in order to run the BLDC motor as shown on link below. General parameters are 3 Phase motor with 4 Poles, 36V, 7.3A rated current, 4000RPM rated speed.

The power board is configured in FOC mode, following the official documentation.

I use the ST Motor Profiler to generate the motor profile.

The problem is that the power board overheats in first seconds of Run.

First calibration is “successful” although it stops at 3000RPM as maximum speed and torque is very low.

At the end of calibration I am not able to recalibrate or use the “play” function to run the motor because the PowerBoard is overheated, ALTHOUGH I get no overheating error as feedback.

If I let the Board cool down some minutes, then I am able to run the board for some seconds until overheating protection stops the motor at about 80C.

No load is added on motor

I have added heatsink with the only difference getting some more seconds of run

On the STM32 NUCLEO board: JP1 open, JP5 (PWR) on E5V side, JP6 (IDD) closed.

On the X-NUCLEO-IHM08M1 expansion board: J9 open, JP3 closed.

jumpers: JP1 and JP2 closed, J5&J6 on the 3-Sh side. Removed capacitors C3, C5 and C7

In motor profiler I tried different number of pole pairs, lower RPM, much lower current (1A) again with no success.

Any idea what could be the issue?

i have BLDC motor with General parameters are 3 Phase motor with 4 Poles, 36V, 7.3A rated current, 4000RPM rated speed.

you can check datasheet on link below

The first question is how many Pair of Poles does this motor have? 2 or 4?

For example the motor bellow

https://www.omc-stepperonline.com/download/57BLR110-36-01.pdf

//For those who want to get depper into the problem :

I am using a Nucleo-F401RE combined with the extension board X-NUCLEO-IHM08M1 in order to run the BLDC motor as shown on link below. General parameters are 3 Phase motor with 4 Poles, 36V, 7.3A rated current, 4000RPM rated speed.

The power board is configured in FOC mode, following the official documentation.

I use the ST Motor Profiler to generate the motor profile.

The problem is that the power board overheats in first seconds of Run.

First calibration is “successful” although it stops at 3000RPM as maximum speed and torque is very low.

At the end of calibration I am not able to recalibrate or use the “play” function to run the motor because the PowerBoard is overheated, ALTHOUGH I get no overheating error as feedback.

If I let the Board cool down some minutes, then I am able to run the board for some seconds until overheating protection stops the motor at about 80C.

No load is added on motor

I have added heatsink with the only difference getting some more seconds of run

On the STM32 NUCLEO board: JP1 open, JP5 (PWR) on E5V side, JP6 (IDD) closed.

On the X-NUCLEO-IHM08M1 expansion board: J9 open, JP3 closed.

jumpers: JP1 and JP2 closed, J5&J6 on the 3-Sh side. Removed capacitors C3, C5 and C7

In motor profiler I tried different number of pole pairs, lower RPM, much lower current (1A) again with no success.

Any idea what could be the issue?

Last edited by a moderator: