Steve Rogers

- 9

- 2

- TL;DR

- Does a transformer with its primary coil and secondary coil intertwined really need a core of iron?

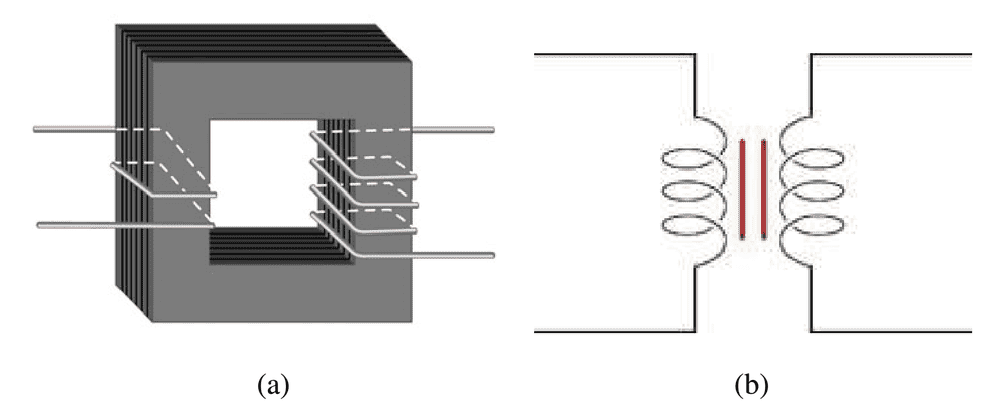

Hi, everyone. I just finished studying the principle on which a transformer works. It relies on Faraday's law of induction. And my high school physics book uses the following picture for illustration:

Roughly speaking, the core of iron is used to pass the magnetic field built by the primary coil to the secondary coil. But I found an interesting video clip on youtube that really confuses me:

Build an electric transformer (DIY)

In this video, a man tries to make a transformer from scratch. The design for his transformer is basically the same as that for a commercial transformer, that is, the primary coil and the secondary coil are wound coaxially. And I'm wondering if the silicon iron sheets he used are that indispensable. After all, the primary coil can now pass its magnetic field on its own. Does anyone have an idea? Thank you.

Roughly speaking, the core of iron is used to pass the magnetic field built by the primary coil to the secondary coil. But I found an interesting video clip on youtube that really confuses me:

Build an electric transformer (DIY)

In this video, a man tries to make a transformer from scratch. The design for his transformer is basically the same as that for a commercial transformer, that is, the primary coil and the secondary coil are wound coaxially. And I'm wondering if the silicon iron sheets he used are that indispensable. After all, the primary coil can now pass its magnetic field on its own. Does anyone have an idea? Thank you.