clab

- 2

- 1

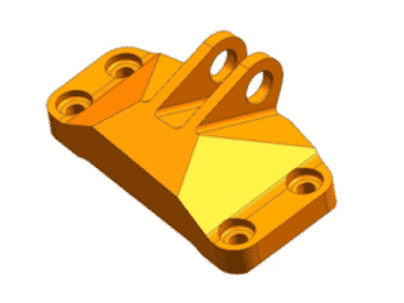

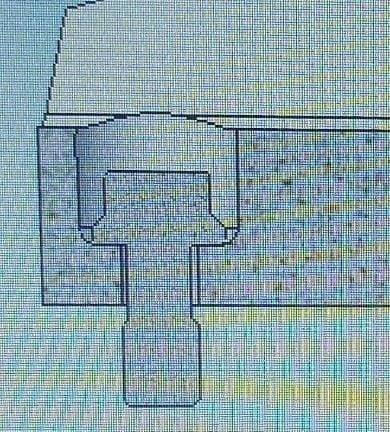

Hi, I have one question related to the boundary conditions I should apply in a Static Structural simulation for the following support.

The support is subjected to the following loading conditions shown below.

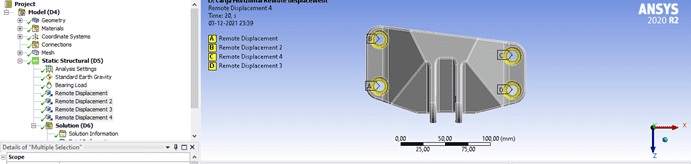

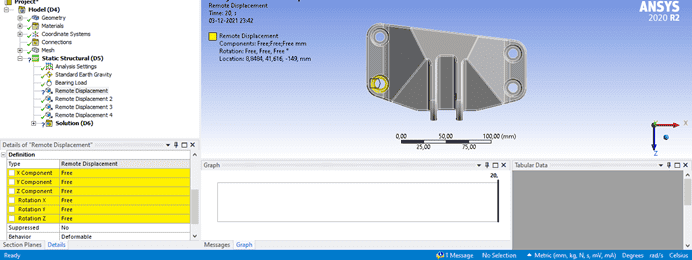

When performing the support edge condition by applying the remote displacement, I must consider the constraints generated by the bolts on both displacement and rotation. Which displacement and rotation components should be free or fixed? (as shown in the last screenshot).

I am considering that the screw only makes contact/pressure with the bracket on the face of the countersunk hole. as shown in the following image.

The support is subjected to the following loading conditions shown below.

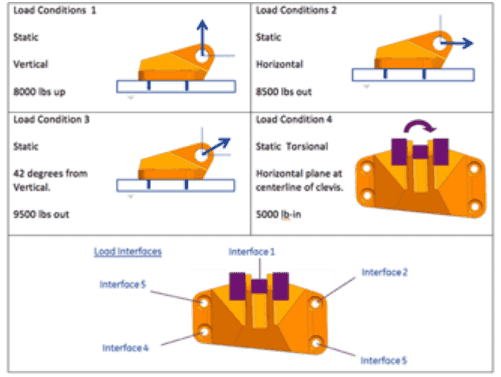

- Interface 1: 0.75 inch diameter pin. The pin is to be considered infinitely stiff.

- Interfaces 2 – 5: 0.375-24 AS3239-26 machine bolt. Nut face 0.405 in. max ID and 0.558 in. min OD. The bolts are to be considered infinitely stiff.

- Load Conditions:

- 1. Max static linear load of 8,000 lbs vertical up.

- 2. Max static linear load of 8,500 lbs horizontal out.

- 3. Max static linear load of 9,500 lbs 42 degrees from vertical.

- 4. Max static torsional load of 5,000 lb-in horizontal at intersection of centerline of pin and midpoint between clevis arms.

When performing the support edge condition by applying the remote displacement, I must consider the constraints generated by the bolts on both displacement and rotation. Which displacement and rotation components should be free or fixed? (as shown in the last screenshot).

I am considering that the screw only makes contact/pressure with the bracket on the face of the countersunk hole. as shown in the following image.