ddice

- 1

- 1

- TL;DR

- Problems generating industrial clear Ice tube. The ice is cracking and we don't know why.

Summary: Problems generating industrial clear Ice tube. The ice is cracking and we don't know why.

Summary: Problems generating industrial clear Ice tube. The ice is cracking and we don't know why.

Hi all!

I'm an engineer from Spain and I'm working in a new project (factory ice).

We have developed a new ice generator but we need our knowledge to solve one problem we have.

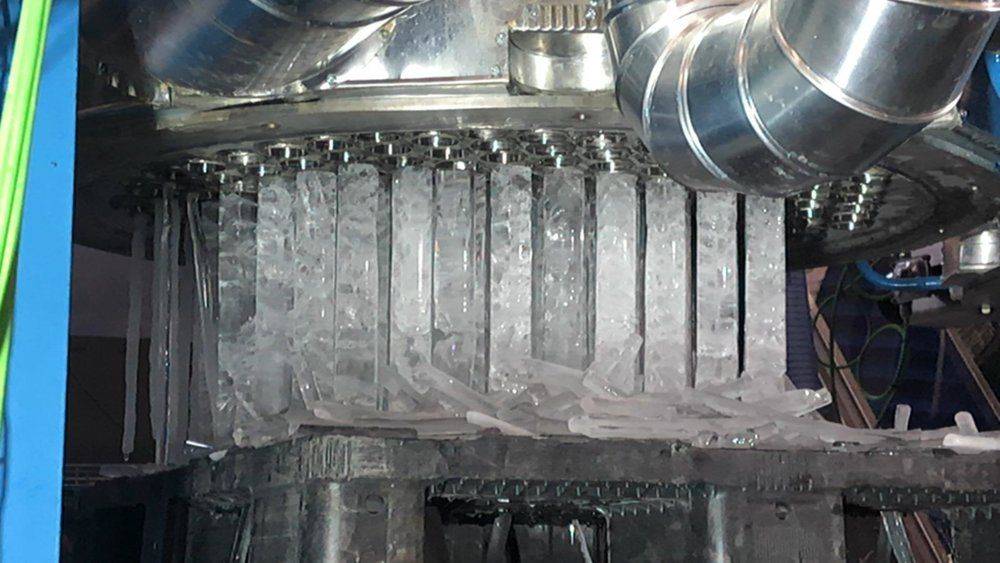

Our ice is cracked and we are looking for "perfect Cristal ice" so we have to make ice without cracking.

We are thinking about the cracking could be taking place in two different processes:

1- During ice generation process (freezing water process)

2- During defrost process (when we defrost the tube to unmold the ice, before cut it)

We generate the ice at -10 Celsius and we unmold the ice about 4, 10 Celsius.

One of our theories is that the temperature stress is too high and the ice crack.

Any expert here could help us?

Thanks in advance.

I attach some pictures when you can see it.

Summary: Problems generating industrial clear Ice tube. The ice is cracking and we don't know why.

Hi all!

I'm an engineer from Spain and I'm working in a new project (factory ice).

We have developed a new ice generator but we need our knowledge to solve one problem we have.

Our ice is cracked and we are looking for "perfect Cristal ice" so we have to make ice without cracking.

We are thinking about the cracking could be taking place in two different processes:

1- During ice generation process (freezing water process)

2- During defrost process (when we defrost the tube to unmold the ice, before cut it)

We generate the ice at -10 Celsius and we unmold the ice about 4, 10 Celsius.

One of our theories is that the temperature stress is too high and the ice crack.

Any expert here could help us?

Thanks in advance.

I attach some pictures when you can see it.