kunalvanjare

- 80

- 2

Sorry for the inactivity on this. Unable to come up with a solution for a centralized system, I have decided to pursue this for one Machine Sump initially and maybe add a machine or two to this just to avoid the insane amount of piping & valves that would be required to control 10 or more machines from one unit.

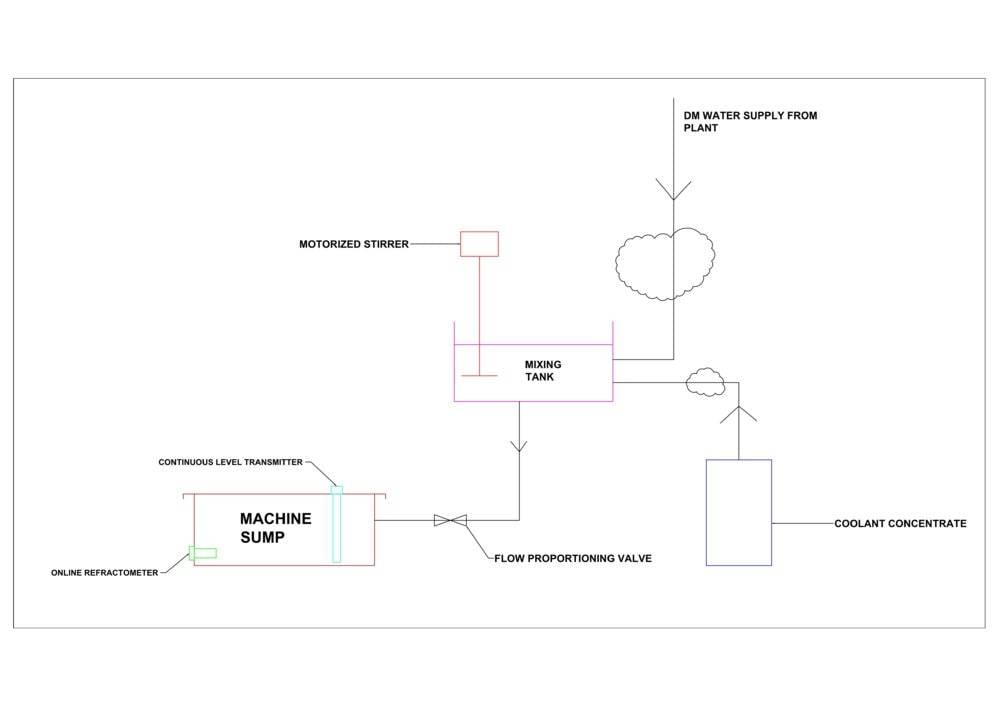

@Asymptotic , I am designing a system as described above and have encountered a problem. Please see this image :-

I'll describe how this works.

1. An online refractometer & continuous level transmitter (capacitive or ultrasonic) continuously monitor the concentration & level of liquid in the machine sump. Both these inputs are fed to the PLC through 4-20 mA.

2. I have another mixing tank with a mechanical motorized stirrer. Depending on the inputs of concentration & level, I will decide the amount of re-fill required (how much volume at what concentration) using a formula which will be fed to the PLC. Refer this tool - http://www.qtstools.com/document_library/tech-resources/Coolants/Refill%20Concentration%20Calculator.xls

3. Now that I know how much liquid & concentration is required to maintain the sump at the desired volume & concentration, I have to fill the mixing tank with the exact amount of DM water (from the DM water supply) & coolant concentrate.

4. After mixing, the mixed coolant shall be transferred to the machine sump.

Now, I have a couple of issues here.

1) Depending on the input of current concentration & current volume of liquid in the machine sump, how do I fill the Mixing Tank with just the right amount of DM water & Coolant concentrate? Consider DM water shall be supplied through piping and not from a tank.

2) If I fill the mixing tank without metering or measuring the volume of DM water & coolant concentrate, can I use a Proportioning or Automatic Flow Control Valve on the outlet of the Mixing Tank? This valve would be synchronized through PLC with the Concentration & Level parameters to supply just the right amount of mixed liquid to maintain correct concentration & liquid level in the machine sump. But in this case, how do I know how much coolant concentrate to draw into the Mixing Tank? Using Venturi Mixers is not possible as the purpose of an automated system is defeated when you have to adjust the orifice opening everytime there is a change in concentration.

Any clarity on the above would be hugely appreciated.

@Asymptotic , I am designing a system as described above and have encountered a problem. Please see this image :-

I'll describe how this works.

1. An online refractometer & continuous level transmitter (capacitive or ultrasonic) continuously monitor the concentration & level of liquid in the machine sump. Both these inputs are fed to the PLC through 4-20 mA.

2. I have another mixing tank with a mechanical motorized stirrer. Depending on the inputs of concentration & level, I will decide the amount of re-fill required (how much volume at what concentration) using a formula which will be fed to the PLC. Refer this tool - http://www.qtstools.com/document_library/tech-resources/Coolants/Refill%20Concentration%20Calculator.xls

3. Now that I know how much liquid & concentration is required to maintain the sump at the desired volume & concentration, I have to fill the mixing tank with the exact amount of DM water (from the DM water supply) & coolant concentrate.

4. After mixing, the mixed coolant shall be transferred to the machine sump.

Now, I have a couple of issues here.

1) Depending on the input of current concentration & current volume of liquid in the machine sump, how do I fill the Mixing Tank with just the right amount of DM water & Coolant concentrate? Consider DM water shall be supplied through piping and not from a tank.

2) If I fill the mixing tank without metering or measuring the volume of DM water & coolant concentrate, can I use a Proportioning or Automatic Flow Control Valve on the outlet of the Mixing Tank? This valve would be synchronized through PLC with the Concentration & Level parameters to supply just the right amount of mixed liquid to maintain correct concentration & liquid level in the machine sump. But in this case, how do I know how much coolant concentrate to draw into the Mixing Tank? Using Venturi Mixers is not possible as the purpose of an automated system is defeated when you have to adjust the orifice opening everytime there is a change in concentration.

Any clarity on the above would be hugely appreciated.