Pinon1977

- 126

- 4

- TL;DR

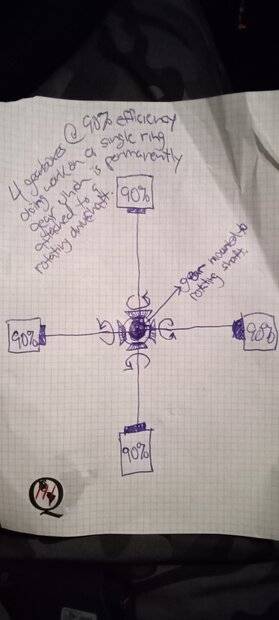

- Trying to determine the overall efficiency of a 4 into one gearbox configuration

So I'm trying to figure out the overall efficiency of this particular gear system. I have four gearboxes, each stationary in and of themselves, all driving a central ring gear which is permanently attached to a rotating shaft. Please see the attached sketch. If each one of the perimeter gearboxes is 90% efficient and they're directly feeding a ring gear that is attached permanently to a drive shaft, what would the overall power transfer efficiency be? One more piece of information, each gearbox has an input power of one horsepower. My first guesstimation would be that one horsepower reduced by 90% efficiency would be 9 horsepower.. but then when you multiply 9 x .9 x .9 v .9?

Last edited by a moderator: