Rx7man

- 425

- 189

I started a project, and where I thought I has a potentiometer position feedback, best I can tell I have an eddy current position sensor, which I'm absolutely not familiar with

The application is a diesel engine injector pump (retrofitting to a different engine, it was from a Komatsu V12, no, I can't look at the original ECU for ideas)

There are two big solenoids (fed by brown wires) (one at the top for changing the timing which does not have position feedback, one below it for varying fuel quantity, which does have position feedback, the plunger of the solenoid moves outward (toward camera))

on the right side there is a dual coil sensor system, the lower one is picks up a rotating nub on the shaft (Max9924 should interface that just fine), but the upper part has a copper ring that slides up and down it, and to the best of my knowledge, that's an eddy current style sensor

different angle on the sensor, right part is the shaft position nub sensor, left part has the moving copper ring

Here's the copper ring

Shaft nub

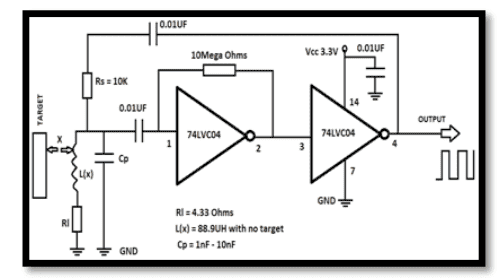

The only circuit diagram I've been able to find, in miserable resolution and with poor details is figure 8 in this article, but it tells me nothing of the output frequency or how it changes, but from my reading it would be between 500khz-1mhz, which is far faster than I'd want to interface to a microcontroller interupt... maybe I could put a 14 bit binary counter inline with the output to get ~50-100hz output?

The only circuit diagram I've been able to find, in miserable resolution and with poor details is figure 8 in this article, but it tells me nothing of the output frequency or how it changes, but from my reading it would be between 500khz-1mhz, which is far faster than I'd want to interface to a microcontroller interupt... maybe I could put a 14 bit binary counter inline with the output to get ~50-100hz output?

https://www.fierceelectronics.com/components/designing-and-building-eddy-current-position-sensor

I have a function generator and a 2 channel scope and was playing around feeding a sine wave to the coil and watching the waveform on the scope, I never did get much for phase shift, but at 75khz seemed to be the resonant frequency in my setup, and at that frequency, moving a copper loop over the sensor did have a large effect on amplitude... my peak-to-peak amplitude went from 1.64V down to 160mV, (when feeding 5V) which is a fair dynamic range, I could increase the feed voltage a bit, rectify it, and put into an ADC... does this sound like a reasonable way to do it?

The application is a diesel engine injector pump (retrofitting to a different engine, it was from a Komatsu V12, no, I can't look at the original ECU for ideas)

There are two big solenoids (fed by brown wires) (one at the top for changing the timing which does not have position feedback, one below it for varying fuel quantity, which does have position feedback, the plunger of the solenoid moves outward (toward camera))

on the right side there is a dual coil sensor system, the lower one is picks up a rotating nub on the shaft (Max9924 should interface that just fine), but the upper part has a copper ring that slides up and down it, and to the best of my knowledge, that's an eddy current style sensor

different angle on the sensor, right part is the shaft position nub sensor, left part has the moving copper ring

Here's the copper ring

Shaft nub

https://www.fierceelectronics.com/components/designing-and-building-eddy-current-position-sensor

I have a function generator and a 2 channel scope and was playing around feeding a sine wave to the coil and watching the waveform on the scope, I never did get much for phase shift, but at 75khz seemed to be the resonant frequency in my setup, and at that frequency, moving a copper loop over the sensor did have a large effect on amplitude... my peak-to-peak amplitude went from 1.64V down to 160mV, (when feeding 5V) which is a fair dynamic range, I could increase the feed voltage a bit, rectify it, and put into an ADC... does this sound like a reasonable way to do it?