t0mm02

- 49

- 0

Hello everyone,

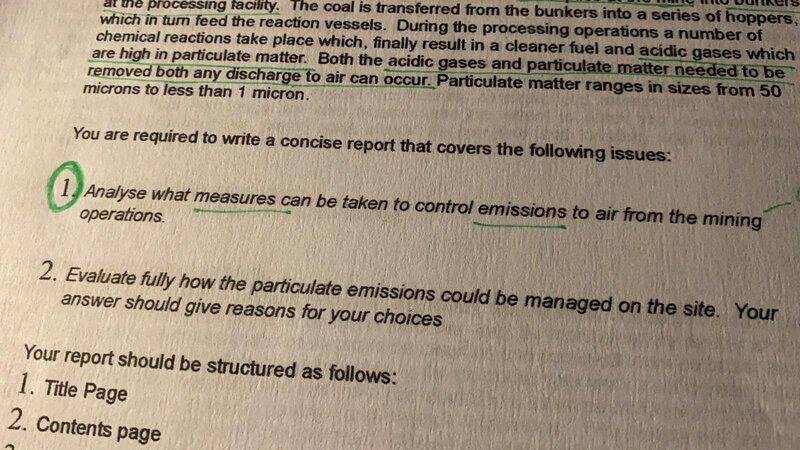

I am sorry if this question looks silly but my tutor has not replied yet and I need to work it out as soon as I can. Could someone tell me if they see any difference question 1 and question 2? Because I genuinely don't and it is driving me crazy. The assignment is about a coal mine and how to prevent emissions

I am sorry if this question looks silly but my tutor has not replied yet and I need to work it out as soon as I can. Could someone tell me if they see any difference question 1 and question 2? Because I genuinely don't and it is driving me crazy. The assignment is about a coal mine and how to prevent emissions