Discussion Overview

The discussion revolves around the challenges of locking a laser to a bow-tie cavity, specifically focusing on the characteristics of the error signal observed during the locking process. Participants explore the nature of the error signal, its expected behavior, and the tuning of servo gains to achieve a stable lock.

Discussion Character

- Technical explanation

- Debate/contested

Main Points Raised

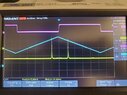

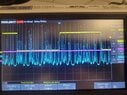

- One participant describes an unexpected error signal with peaks rather than a flat line when locking the laser, indicating a potential issue with the locking process.

- Another participant clarifies terminology regarding the error signal and suggests tuning the servo gains to stabilize the lock.

- A participant mentions that the amplitude of the peaks increases with better locking, raising questions about the nature of these peaks.

- There are suggestions to record the error signal when the laser is unlocked and to compare it with the control signal to diagnose the issue further.

- Some participants inquire about the specifics of the laser servo being used, indicating that the type of servo may influence the locking behavior.

- There is a discussion about whether the signal being observed is indeed the transmission signal from the photodiode or if it is related to the locking mechanism itself.

Areas of Agreement / Disagreement

Participants do not reach a consensus on the cause of the observed error signal behavior, and multiple competing views remain regarding the interpretation of the signal and the tuning process.

Contextual Notes

Participants express uncertainty about the definitions and measurements involved, such as the vertical scale of the oscilloscope trace and the nature of the peaks in the error signal. There are also unresolved questions about the relationship between the error signal and the transmission photodiode signal.

Who May Find This Useful

This discussion may be useful for individuals working with laser locking systems, particularly those involved in experimental setups requiring precise control of laser frequencies.