omgcornflakes

- 1

- 0

- TL;DR

- Need to heat 8-12 metal plates to 41C for 2 hours.

(In opening, hi. I'm a lawyer, not a physicist, and I'm entirely out of my depth here.)

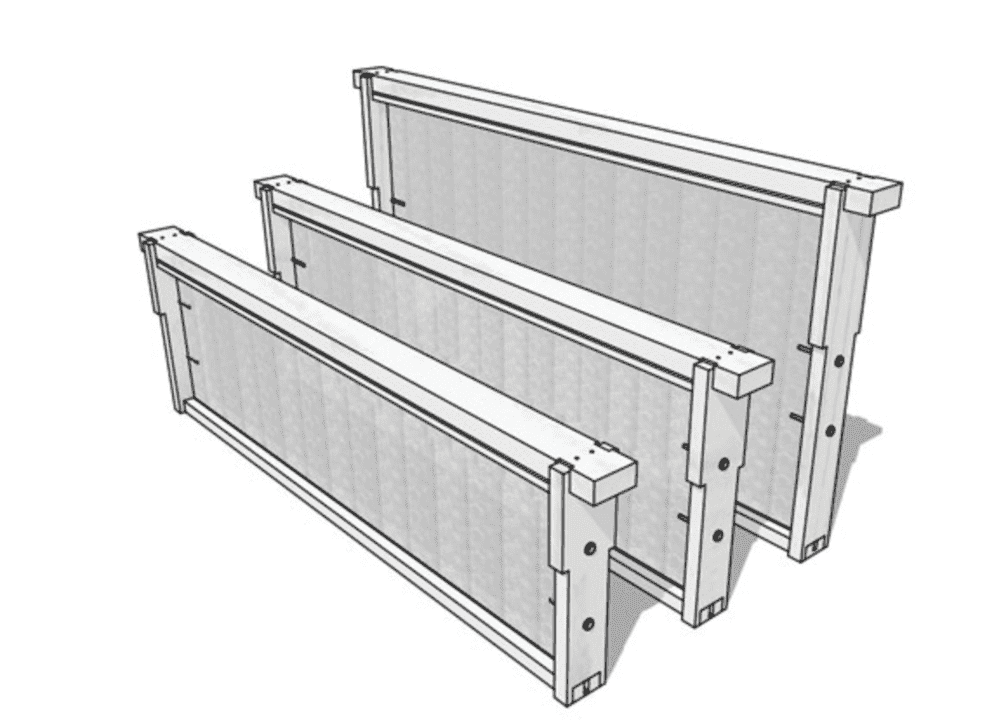

I need to make roughly 8 wooden frames (19 inches x 1-1/16 inches x 9-1/8 inches). Into each, I'd like to place a thin metal plate with hexagonal cells (5.27 mm cell diameter) pressed into them. I need to heat these cells (or, more specifically, what will be the contents of these cells) to 41C and maintain that temperature for 2 hours. It needs to be *fairly* precise (+/- 2C, more or less) and something that can be repeated at 2 week (give or take) intervals.

The frames/plates will be perpendicular to the ground and parallel to each other in a wooden box. No heating element (other than the plates, which will be coated in wax) can be exposed.

Heat source ideally needs to be above the frames/plates and must be fairly easy to lift off/remove. Solar would be workable or, failing that, something else that can safely be left outside.

So my question is, mostly...how do I heat these plates?

I need to make roughly 8 wooden frames (19 inches x 1-1/16 inches x 9-1/8 inches). Into each, I'd like to place a thin metal plate with hexagonal cells (5.27 mm cell diameter) pressed into them. I need to heat these cells (or, more specifically, what will be the contents of these cells) to 41C and maintain that temperature for 2 hours. It needs to be *fairly* precise (+/- 2C, more or less) and something that can be repeated at 2 week (give or take) intervals.

The frames/plates will be perpendicular to the ground and parallel to each other in a wooden box. No heating element (other than the plates, which will be coated in wax) can be exposed.

Heat source ideally needs to be above the frames/plates and must be fairly easy to lift off/remove. Solar would be workable or, failing that, something else that can safely be left outside.

So my question is, mostly...how do I heat these plates?