Don't take this the wrong way, but when you brake a brake, something slows down, while when you break a brake it does not.

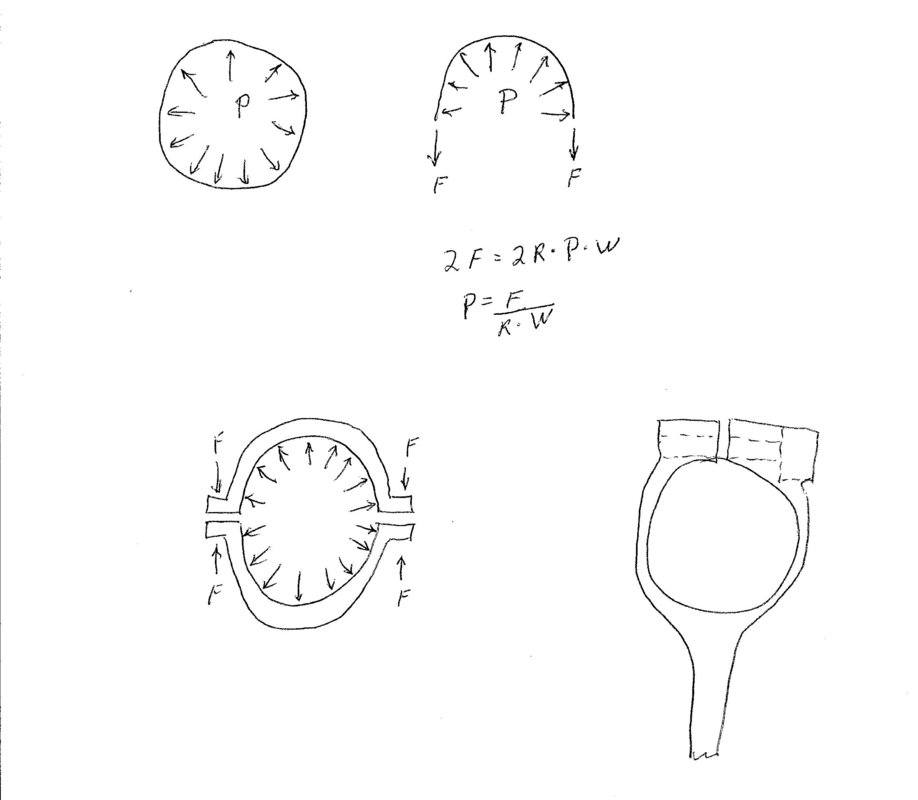

The top left sketch in the following sketch represents a thin wall pressure vessel. The top right sketch is the free body diagram for a thin wall pressure vessel. The radius is R, the pressure is P, the length (or width) is W, and the force in each wall is F. The total force 2F is the pressure times the projected (not the actual) area, so 2F = 2R*P*W. Solving for P, we get P = F / (R*W).

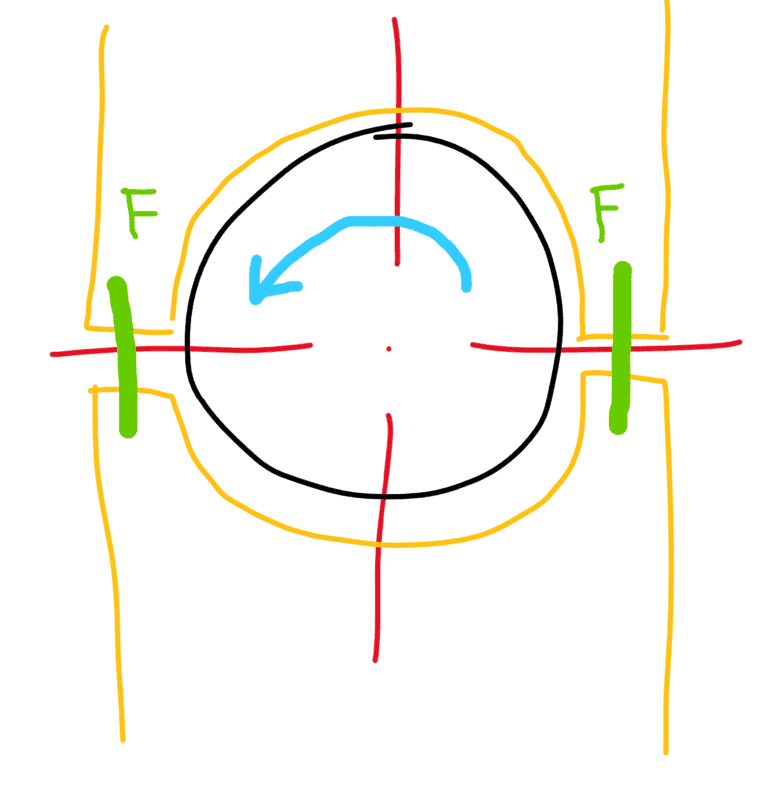

The lower left sketch is the same as the top right, except it is a simplified representation of a thin wall bolted clamp, where the bolt force is F. Thin is relative. In clamp fits, thin means that a small (definitely less than 10%) fraction of the clamp force is needed to elastically deform the clamp to fit to the shaft. If the clamp is very thin (such as in a hose clamp), the initial fit can be very loose. A 2" hose clamp will easily pull into fit a 1" hose. If the clamp is thicker, the initial fit may have as little as 0.001" clearance. If you can tighten the bolt(s) finger tight and feel the clamp gripping the shaft, you are good. If finger tight does not make it grip the shaft, you may need to redesign the clamp or do further analysis using FEA or both.

When the force to get the clamp in proper contact with the shaft is small, then we can assume that 100% of the bolt force is going to clamping force, and none of the bolt force is pulling the clamp up to the shaft. Then we can use the equation from above: P = F / (R*W), where P is the pressure between the clamp and the shaft.

The total normal force between the clamp and the shaft is pressure times area, so

Normal Force = (F / (R*W)) * 2*PI*W.

The torque is the Normal Force times the radius times the coefficient of friction:

Torque = (F / (R*W)) * 2*PI*W * R * mu.

Cancel and rearrange: Torque = 2*PI*F*mu*R.

The bottom right sketch shows a typical implementation of a clamp fit. Note that, when the clamp can flex to fit the shaft, one bolt has exactly the same total clamp force and friction torque as two bolts on opposite sides. If you need to convince yourself of this, look at the bottom left sketch, and replace one of the bolts with a continuation of the clamp. Then cut it and do an FBD.

Note the dashed lines in the bottom right sketch that represent the bolt hole. The bolt body is very close to the shaft. These type of components work best when the bolt is as close as possible to the shaft. It is normal for the bolt hole to break out into the clamping surface.

One way to mount a brake disk to a shaft is by using a shaft collar:

Tap holes in the side of the shaft collar, mount it to the shaft, then bolt the brake disk to the shaft collar. If purchased shaft collar is not suitable, you may need to design your own. Be sure to calculate both the slip torque and the bolted joint for the disk. And remember your safety factors.

Note that if the clamp is too rigid, and clearance too large, to conform to the shaft, then the slip torque is only 4*F*mu*R.