Tinokoloski

- 5

- 0

Hi!

I am making an aeolipile as a school project, and I was wondering if you could calculate the rpm.

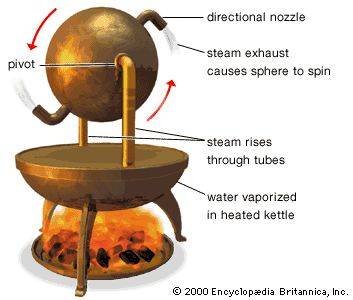

This is the basic principle of an aeolipile.

You should be able to calculate the rotating velocity right? Knowing the mass and ignoring any resistance.

But then you'll need the rotating force. I looked at the rocket equation, but you need to know the exiting gas velocity for that. The diameter of the nozzle is 3mm, would it be possible to calculate the velocity steam could move out of such a nozzle after calculating the pressure inside the hollow ball?

Thanks in advance!

Tino

I am making an aeolipile as a school project, and I was wondering if you could calculate the rpm.

This is the basic principle of an aeolipile.

You should be able to calculate the rotating velocity right? Knowing the mass and ignoring any resistance.

But then you'll need the rotating force. I looked at the rocket equation, but you need to know the exiting gas velocity for that. The diameter of the nozzle is 3mm, would it be possible to calculate the velocity steam could move out of such a nozzle after calculating the pressure inside the hollow ball?

Thanks in advance!

Tino

Best wishes for your project

Best wishes for your project