Will_SPHS

- 18

- 4

Yesterday, I made a thread about creating gears in Inventor. I successfully created them, but now I have a few questions regarding material strength.

Background:

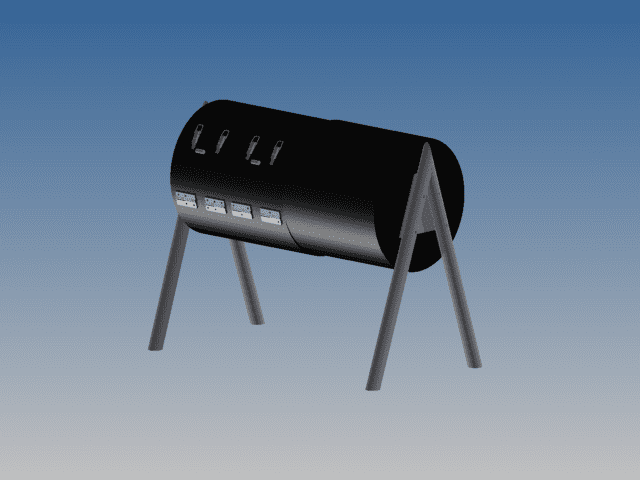

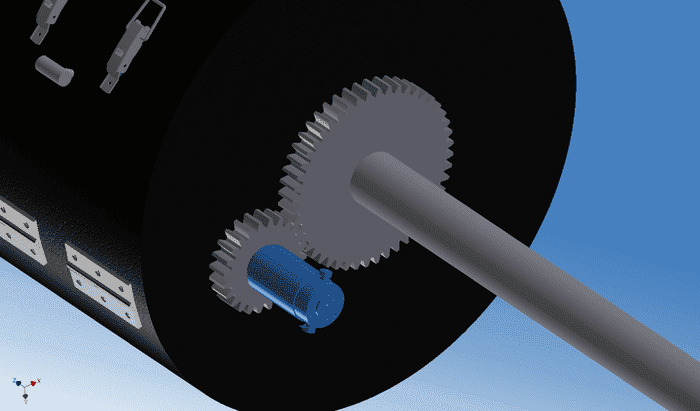

I am making an autonomously rotating compost tumbler for an engineering class. The design consists of a drum surrounding an axle. The drum is turned by a motor and gear system.

I need to determine the materials for the gear system, the support poles, the axle, and the triangular support plates. The drum is made out of HDPE. This product would theoretically be mass-produced, so I am looking to keep the material cost as low as possible. I have a spreadsheet with some material information here.

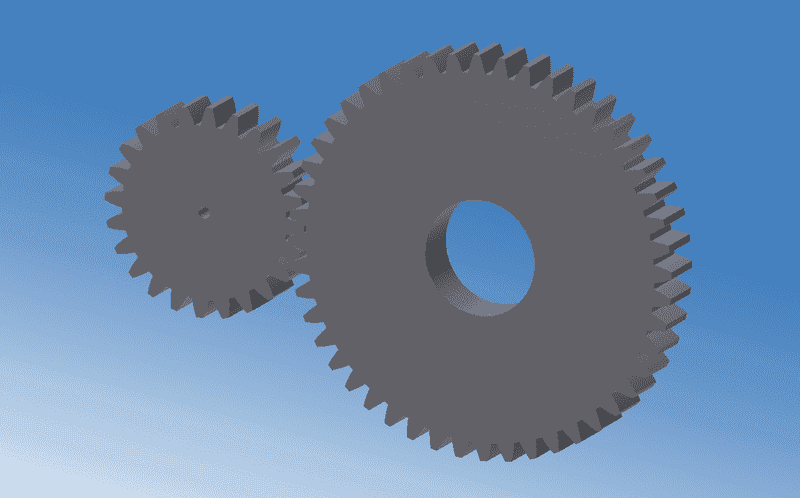

What material can the gears be made out of to keep costs as low as possible? I was thinking about some sort of plastic that can be injection molded, but I don't know how I would go about calculating gear teeth strength.

Should the supports, plates, and axle be made out of galvanized steel or aluminum? I would prefer to keep them all the same material. Galvanized steel is heavier and more expensive but also stronger, while aluminum offers more corrosion resistance. Either way, I need to be able to show calculations justifying my choice. I'm not sure how to calculate the strength since they are angled.

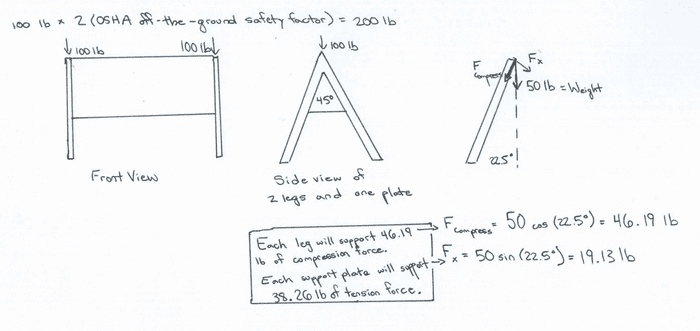

The maximum weight of the device when full shouldn't be more than 100 lb, but with OSHA safety factors, I would prefer to plan for at least 200 lb.

Other info:

The gears have a 1:2 gear ratio. The input torque from the motor (the blue cylinder in the third picture) is 7.8 lb*ft, and the maximum balancing torque of the drum is 8.35 lb*ft. The drum diameter is 1'.

The angle between the supports is around 45 degrees. I don't have the exact number with me right now.

Edit:

I did some calculations to get there to be 46 lb of compression force on each leg, and 39 lb of tension force on each support plate. The compost tumbler doesn't have the weight evenly distributed, but I just had each pair of supports/support plate with 100 lb of weight. I'm not sure if I did it right, but the numbers sound okay to me.

Edit 2:

I am currently leaning towards:

6061-T6 Aluminum

Structural Pipe 3/4" SCH 40 (1.05 OD X .113W) 0.39

Background:

I am making an autonomously rotating compost tumbler for an engineering class. The design consists of a drum surrounding an axle. The drum is turned by a motor and gear system.

I need to determine the materials for the gear system, the support poles, the axle, and the triangular support plates. The drum is made out of HDPE. This product would theoretically be mass-produced, so I am looking to keep the material cost as low as possible. I have a spreadsheet with some material information here.

What material can the gears be made out of to keep costs as low as possible? I was thinking about some sort of plastic that can be injection molded, but I don't know how I would go about calculating gear teeth strength.

Should the supports, plates, and axle be made out of galvanized steel or aluminum? I would prefer to keep them all the same material. Galvanized steel is heavier and more expensive but also stronger, while aluminum offers more corrosion resistance. Either way, I need to be able to show calculations justifying my choice. I'm not sure how to calculate the strength since they are angled.

The maximum weight of the device when full shouldn't be more than 100 lb, but with OSHA safety factors, I would prefer to plan for at least 200 lb.

Other info:

The gears have a 1:2 gear ratio. The input torque from the motor (the blue cylinder in the third picture) is 7.8 lb*ft, and the maximum balancing torque of the drum is 8.35 lb*ft. The drum diameter is 1'.

The angle between the supports is around 45 degrees. I don't have the exact number with me right now.

Edit:

I did some calculations to get there to be 46 lb of compression force on each leg, and 39 lb of tension force on each support plate. The compost tumbler doesn't have the weight evenly distributed, but I just had each pair of supports/support plate with 100 lb of weight. I'm not sure if I did it right, but the numbers sound okay to me.

Edit 2:

I am currently leaning towards:

6061-T6 Aluminum

Structural Pipe 3/4" SCH 40 (1.05 OD X .113W) 0.39

Last edited: