decaf14

- 23

- 7

- TL;DR

- How to estimate heating of a wire

Hello,

I've done some background research on this, and answers seem to vary. I would like to calculate the amount of heating in a wire. Let's say I want to heat a wire up to 60 degrees. I have 1 W of power and 150 mA of current at my disposal to do so. How could I estimate the wire diameter required for this?

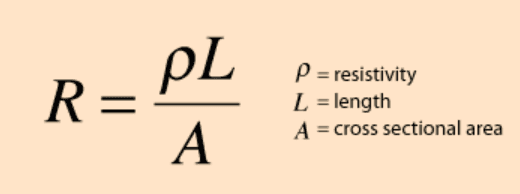

Here are my thoughts based on what I've read: there is no easy analytical expression, but I have two expressions at my disposal. One for resistance of a wire given length, resistivity, and cross sectional area. The other would simply be power: P = I^2 * R

These equations would allow me to calculate perfectly the wire diameter and length for a certain power dissipation. However, I would not know how to relate this to temperature rise.

The other option, which I'm more tempted to do at this point, would be to create a power vs. temperature curve for certain diameter wire using a microcontroller.

I've done some background research on this, and answers seem to vary. I would like to calculate the amount of heating in a wire. Let's say I want to heat a wire up to 60 degrees. I have 1 W of power and 150 mA of current at my disposal to do so. How could I estimate the wire diameter required for this?

Here are my thoughts based on what I've read: there is no easy analytical expression, but I have two expressions at my disposal. One for resistance of a wire given length, resistivity, and cross sectional area. The other would simply be power: P = I^2 * R

These equations would allow me to calculate perfectly the wire diameter and length for a certain power dissipation. However, I would not know how to relate this to temperature rise.

The other option, which I'm more tempted to do at this point, would be to create a power vs. temperature curve for certain diameter wire using a microcontroller.