Discussion Overview

The discussion revolves around the manufacturing processes of screws and springs, with a focus on materials processing aspects such as cooling from the melt and subsequent deformation processing. Participants seek references and technical details related to these manufacturing methods.

Discussion Character

- Exploratory

- Technical explanation

- Conceptual clarification

Main Points Raised

- One participant requests quality references on the manufacturing of screws and springs, emphasizing the importance of materials processing.

- Another participant provides a link to a site that offers a brief description of the manufacturing processes.

- A participant notes that screws are typically made from low to medium carbon steel wire, mentioning alternative materials like stainless steel and brass, and highlights the significance of metal quality.

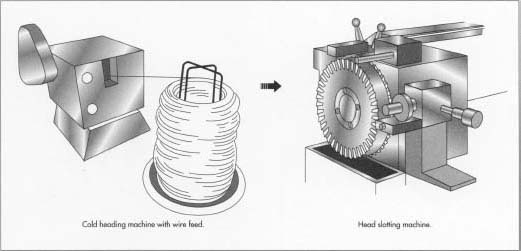

- Details are shared about the cold heading machine process for screws, including cutting wire and forming heads.

- One participant asks for more technical information regarding the manufacturing processes.

- A participant points out that heat treatment is critical for both screws and springs and suggests that springs are made from similar materials and processes.

- Another participant references a table indicating various alloys used in manufacturing and mentions processes like quenching and tempering.

- The original poster expresses gratitude for the responses but indicates a limitation in providing further details due to the nature of their independent research project.

Areas of Agreement / Disagreement

Participants generally agree on the importance of material quality and heat treatment in the manufacturing of screws and springs. However, there is no consensus on the level of technical detail available or required, and multiple viewpoints on the specifics of manufacturing processes remain present.

Contextual Notes

The discussion lacks specific assumptions about the types of screws and springs being referenced, and there are unresolved questions regarding the depth of technical information available. The participants do not clarify the scope of their inquiries fully.

Who May Find This Useful

This discussion may be useful for individuals interested in manufacturing processes, materials science, and engineering, particularly those researching screws and springs.