Muted

- 7

- 0

Hi,

I made an electronics project but I'm having some mechanical problems. Particularly, I'm having issues finding a good clutch for my problem.

What I'm trying to do:

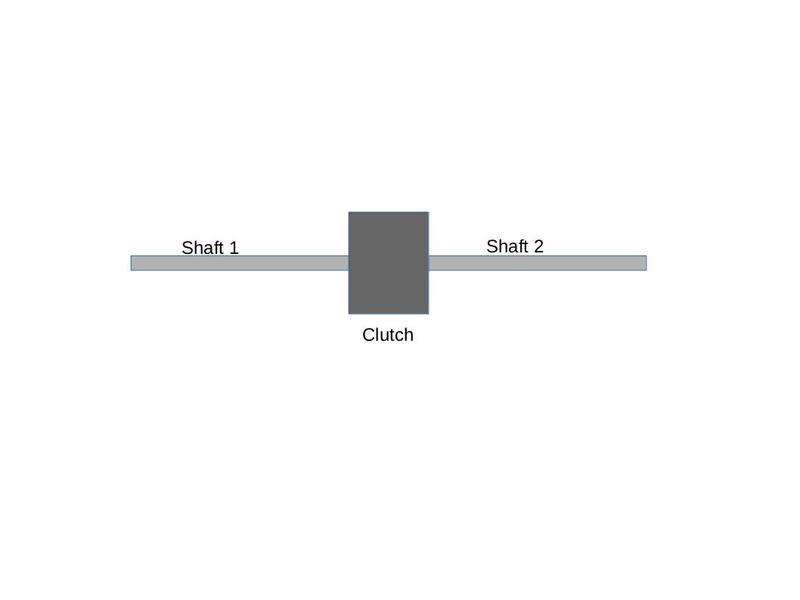

A motor is connected to shaft 1, a human can manually rotate shaft 2.

I want that when the motor isn't doing anything, a human can easily rotate shaft 2. In case it matters, the human will rotate the shaft at most 3 rotations in either direction. When the motor rotates, both shaft 1 and shaft 2 need to move.

The solution I came up with:

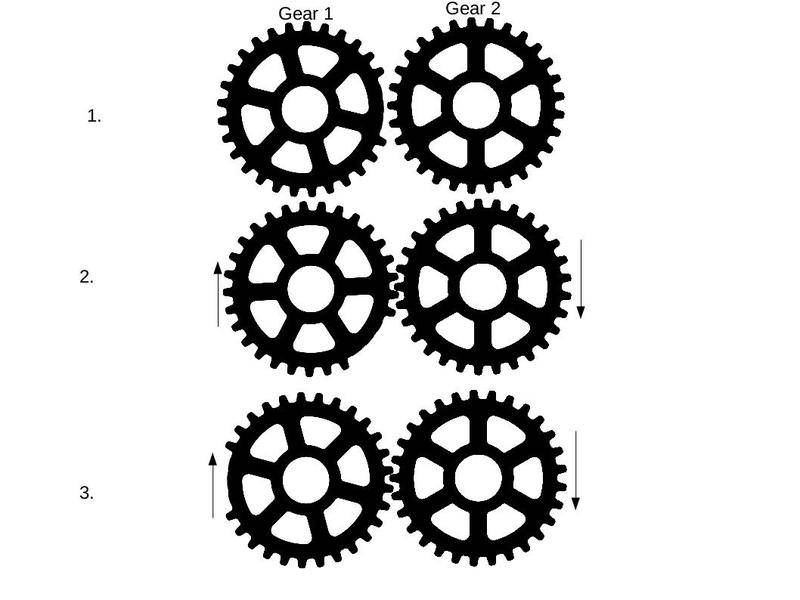

1) gear 1 and gear2 are not engaged, hence gear 2 can rotate freely when the motor is not moving

2) The motor is turning, the gears interlock and so gear2 turns

3) continues until back in position 1

There are a few problems such as you need to be sure that when motor is at rest, there are no gears interlocking. However I might be able to find a solution for this. My biggest problem however is that if the motor's batteries die when it is engaged, there is no way that the user will be able to rotate shaft 2. Any solutions are always welcome =) Thanks!

I made an electronics project but I'm having some mechanical problems. Particularly, I'm having issues finding a good clutch for my problem.

What I'm trying to do:

A motor is connected to shaft 1, a human can manually rotate shaft 2.

I want that when the motor isn't doing anything, a human can easily rotate shaft 2. In case it matters, the human will rotate the shaft at most 3 rotations in either direction. When the motor rotates, both shaft 1 and shaft 2 need to move.

The solution I came up with:

1) gear 1 and gear2 are not engaged, hence gear 2 can rotate freely when the motor is not moving

2) The motor is turning, the gears interlock and so gear2 turns

3) continues until back in position 1

There are a few problems such as you need to be sure that when motor is at rest, there are no gears interlocking. However I might be able to find a solution for this. My biggest problem however is that if the motor's batteries die when it is engaged, there is no way that the user will be able to rotate shaft 2. Any solutions are always welcome =) Thanks!