- #1

Guilty Spark

- 31

- 0

Hey guys!

I've always been curious what would happen if I used air valves and regulators to mix different pressures of air together?

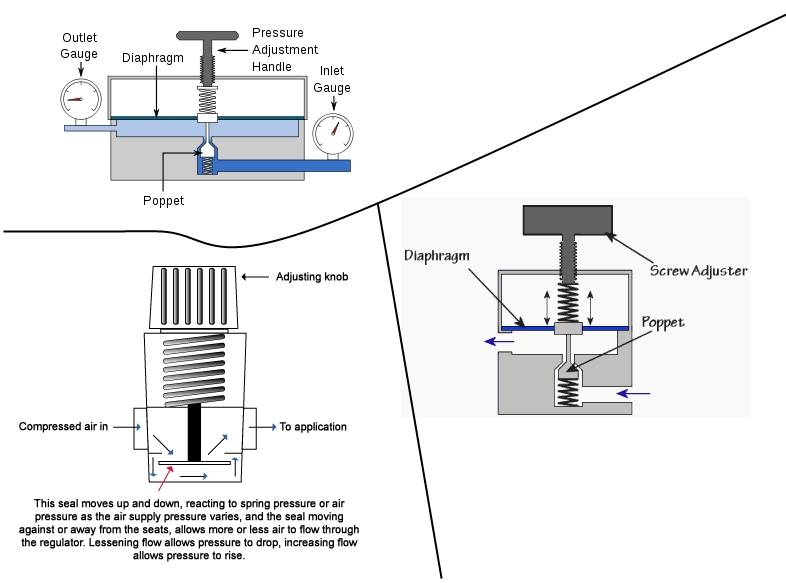

For reference I spliced a few diagrams into one here:

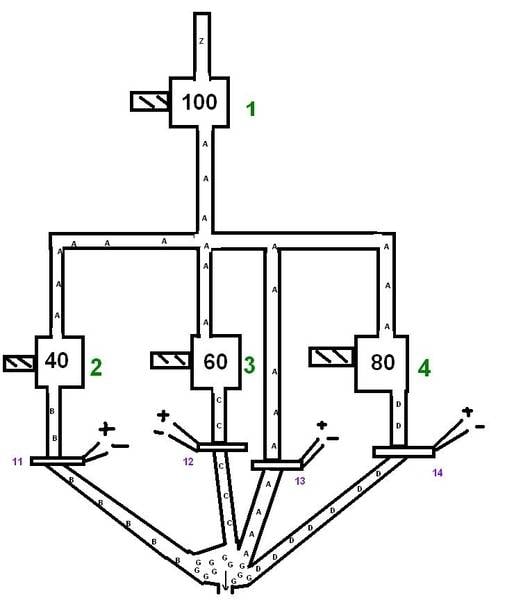

And I made a picture of the setup I'm imagining with some nice labels so we all know what part to refer to!

Assuming the valves are all open, I'm guessing you get 100psi out correct? You can't possibly have more than what you put in?

My main problem is combinations of valves- ie: what happens to pressure "G" if only valves "11" and "12" are open?

Yielding a supply of 40psi and 60psi./

Assume room temperature air, fixed pipe size.. (1/4") I guess..

Anyways, what do you think?

I've always been curious what would happen if I used air valves and regulators to mix different pressures of air together?

For reference I spliced a few diagrams into one here:

And I made a picture of the setup I'm imagining with some nice labels so we all know what part to refer to!

Assuming the valves are all open, I'm guessing you get 100psi out correct? You can't possibly have more than what you put in?

My main problem is combinations of valves- ie: what happens to pressure "G" if only valves "11" and "12" are open?

Yielding a supply of 40psi and 60psi./

Assume room temperature air, fixed pipe size.. (1/4") I guess..

Anyways, what do you think?