- #1

maxitaxi

- 1

- 0

Hello,

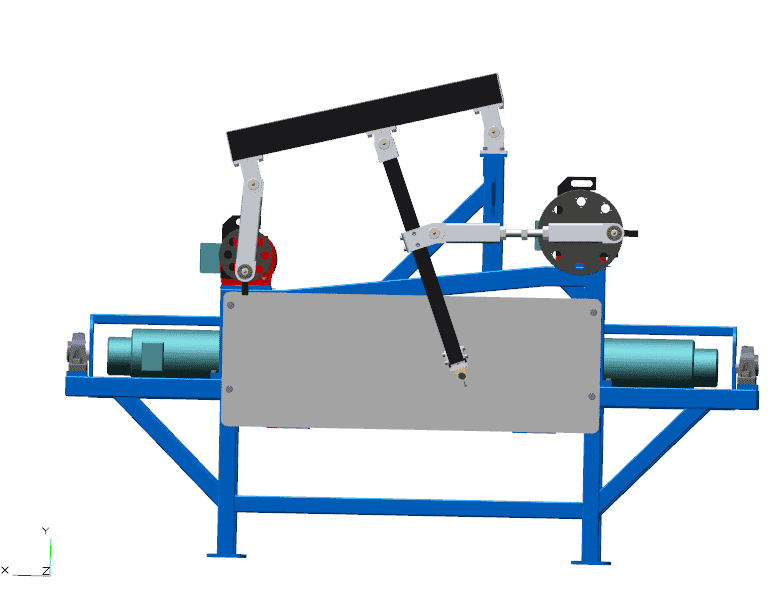

On the image below is a test pendelum for rock wool production. The pendelum is driven by two induction motors. When the right motor makes one revolution, the left motor makes two revolutions. The motors are positionally locked (example: when the right motor is at 35.3° the left motor is at 70.6°). The above part works OK.

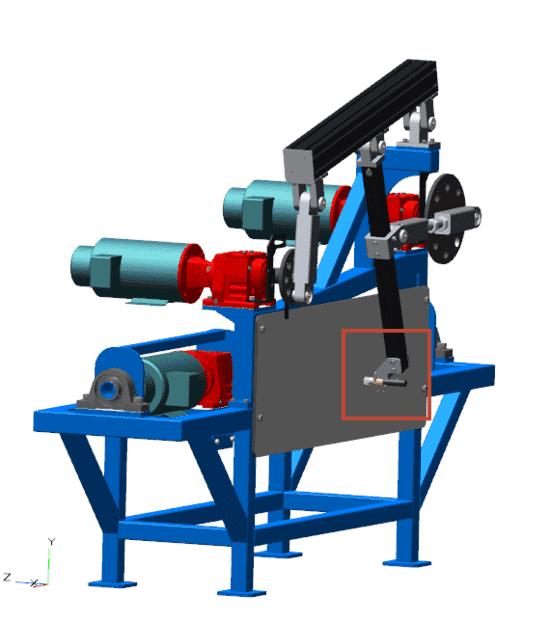

Currently we are using a simple analog procedure (marker and whiteboard) to plot the position of the pendelum (shown on the image below).

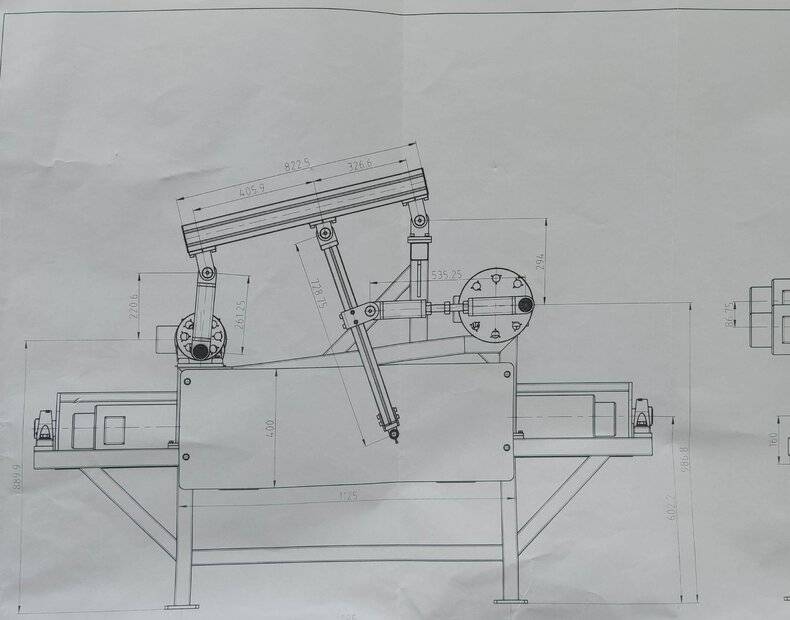

On the image below are the mesurements of the moving parts [mm]. The position of both motors at any given time is known. The speed at any given time is also known (nominal speed is 1500 rpm).

My question is how can movement of this sort of pendelum (where the marker is located) be described with equations. It would be a lot more transparent and easier to analyze to have the pendelum moevement data in digital form.

Thank you for your answer in advance.

Regards.

On the image below is a test pendelum for rock wool production. The pendelum is driven by two induction motors. When the right motor makes one revolution, the left motor makes two revolutions. The motors are positionally locked (example: when the right motor is at 35.3° the left motor is at 70.6°). The above part works OK.

Currently we are using a simple analog procedure (marker and whiteboard) to plot the position of the pendelum (shown on the image below).

On the image below are the mesurements of the moving parts [mm]. The position of both motors at any given time is known. The speed at any given time is also known (nominal speed is 1500 rpm).

My question is how can movement of this sort of pendelum (where the marker is located) be described with equations. It would be a lot more transparent and easier to analyze to have the pendelum moevement data in digital form.

Thank you for your answer in advance.

Regards.