SR71

- 1

- 0

- TL;DR

- Motor sizing for wheel endurance testing

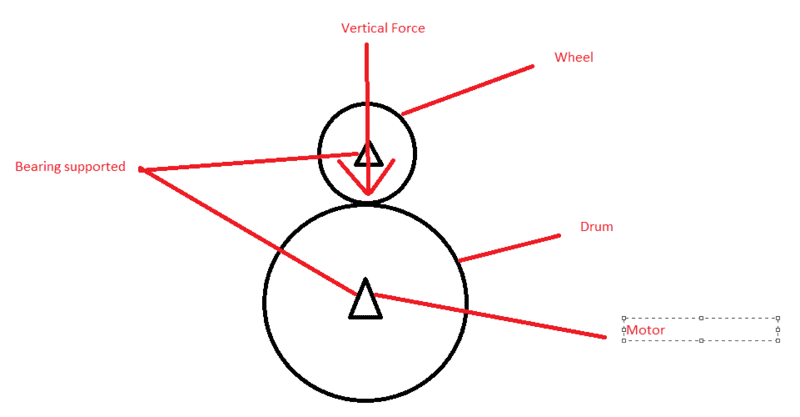

I am working with a wheel endurance testing application. I am trying to size a motor for the system. Basically, I have a drum which has to be rotated by the motor. I have different size wheels that I have to test. The motor is supposed to rotate the drum and then the wheel is pushed onto the drum with a force.

My question is when I want to find the torque (Fx perpendicular distance) do I use the radius of the drum or the radius of the wheel being tested? Currently, I am using the radius of the drum as the wheel is being pushed onto the drum but this gives me huge numbers as the wheel is pushing with 1000-2500 lbs of force.

Thank you in advance.

Link:

My question is when I want to find the torque (Fx perpendicular distance) do I use the radius of the drum or the radius of the wheel being tested? Currently, I am using the radius of the drum as the wheel is being pushed onto the drum but this gives me huge numbers as the wheel is pushing with 1000-2500 lbs of force.

Thank you in advance.

Link:

Last edited by a moderator: