Brian in Victoria BC

- 34

- 30

- TL;DR

- Proof of concept Solar tracking based on a timer, that switches airlift pumps on and off to move floats that rotate one or multiple solar panels.

Ultimately, this idea is about tracking solar cookers for poor countries. And that is partly why I made it so low tech.

It's much easier to demonstrate that it works to move solar panels so my first proof of concept has a solar panel. Equatorial mount is just setting something on an axis that points at the north star. (Technically, an axis that is in line with the earth's axis), pointing your payload at the required target (the sun) and then rotating the payload at 15 degrees per hour. Then over the course of the seasons, you will need to occasionally adjust you "declination angle" up or down by up 23degrees, Once to twice a week around the equinoxes and much less around high summer and low winter.

In my proof of concept, I let it run from 8.45 am (when first direct sun comes over my neighbor house until about 6 pm when the sun goes behind my roof. Then I open a valve and let the water drain back into the lower container. This resets the solar panel ready to go for the next morning. This is proving to be more accurate than I had expected. Of course my proof of concept is pretty flimsy, but even so, a lot more accurate than I had expected.

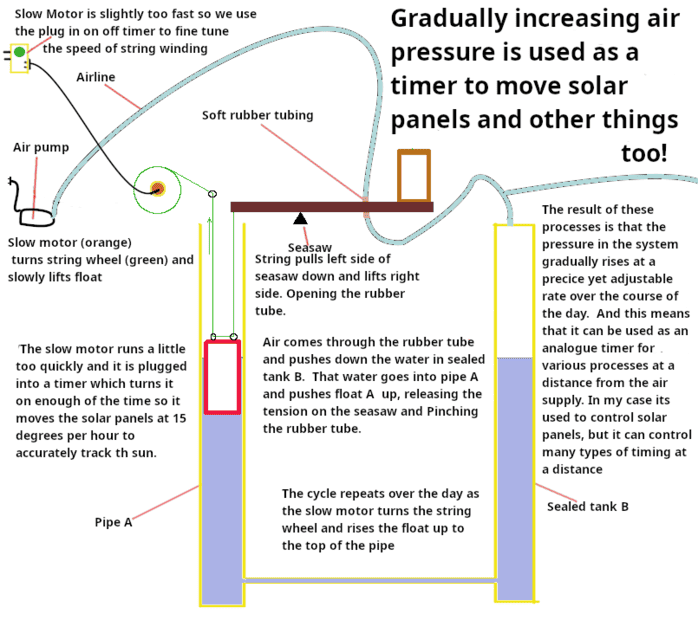

This picture/diagram shows the outside part of my setup

And this diagram shows the inside portion, I will add another picture to show the inside portion.

Here is the current version of the indoor part in the pipe,

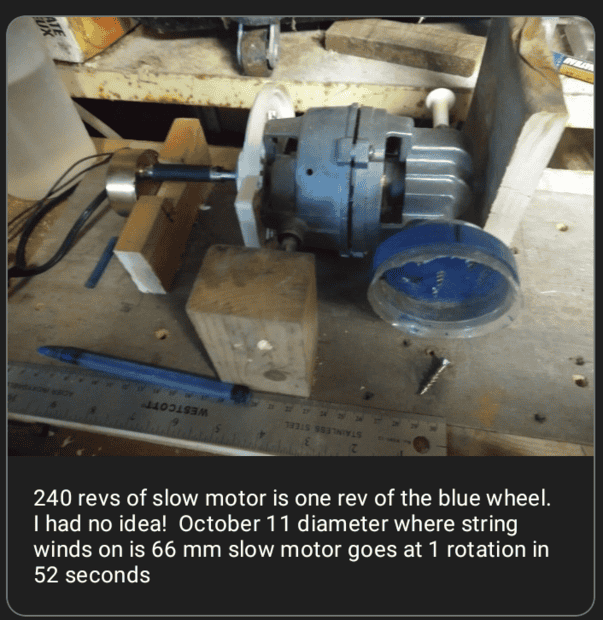

So, anyways, the blue wheel slowly winds up some fishing line to pull up the float. The synchronous motor turns the gearbox of an old fan, that turns the piece that moved the fan from side to side (this is where the blue plastic wheel is attached.

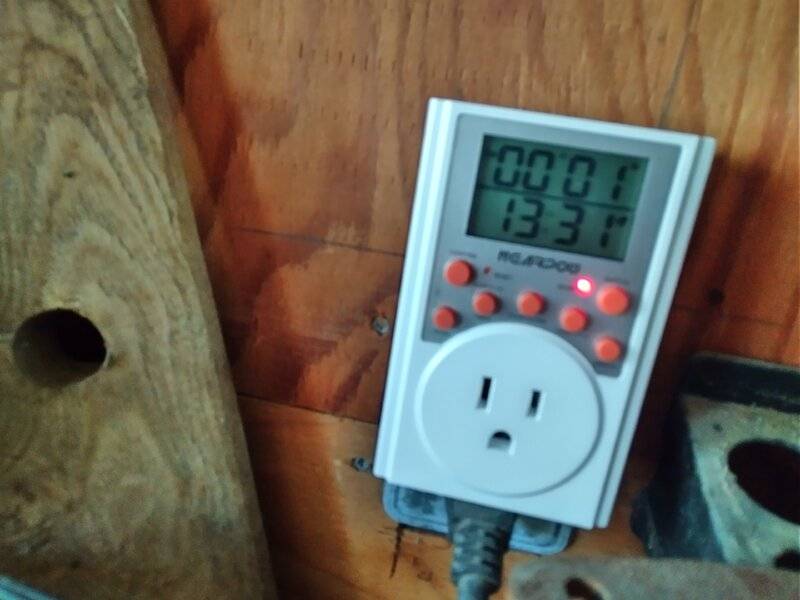

The last thing is the programable switch that turns on and off the circuit the right amount to get the solar panel turning at exactly 15 degrees per hour.

It's much easier to demonstrate that it works to move solar panels so my first proof of concept has a solar panel. Equatorial mount is just setting something on an axis that points at the north star. (Technically, an axis that is in line with the earth's axis), pointing your payload at the required target (the sun) and then rotating the payload at 15 degrees per hour. Then over the course of the seasons, you will need to occasionally adjust you "declination angle" up or down by up 23degrees, Once to twice a week around the equinoxes and much less around high summer and low winter.

In my proof of concept, I let it run from 8.45 am (when first direct sun comes over my neighbor house until about 6 pm when the sun goes behind my roof. Then I open a valve and let the water drain back into the lower container. This resets the solar panel ready to go for the next morning. This is proving to be more accurate than I had expected. Of course my proof of concept is pretty flimsy, but even so, a lot more accurate than I had expected.

This picture/diagram shows the outside part of my setup

And this diagram shows the inside portion, I will add another picture to show the inside portion.

Here is the current version of the indoor part in the pipe,

So, anyways, the blue wheel slowly winds up some fishing line to pull up the float. The synchronous motor turns the gearbox of an old fan, that turns the piece that moved the fan from side to side (this is where the blue plastic wheel is attached.

The last thing is the programable switch that turns on and off the circuit the right amount to get the solar panel turning at exactly 15 degrees per hour.

Last edited by a moderator: