- 30,090

- 7,379

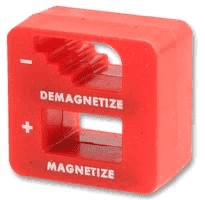

I need something to demagnetise my workshop tools. Recently, I've been turning and milling steel parts and everything is collecting a lot of swarf (chips). Somehow, it's all getting magnetised at a ridiculous rate and the stickiness is beating my vacuum cleaner. I was looking into the idea of buying a 'proper' degaussing machine but they tend to be pricey. I see an alternative that's advertised everywhere. It obviously has an array of permanent magnets inside and they must be arranged so that moving a hand tool through it will alternate polarity of field, getting progressively weaker. This sort of thing is now possible, since really powerful permanent magnets became so cheap.

But it stuck me that the best you can hope to do would be to reduce the residual magnetisation in the tool to the step size in the graduations of field strength. Has anyone ever used one and was it any good?

Unless it's good enough to stop my swarf-pickup problem I may have to try a DIY solution with an old transformer and a hacksaw(?*****)

Image from Farnell Website

But it stuck me that the best you can hope to do would be to reduce the residual magnetisation in the tool to the step size in the graduations of field strength. Has anyone ever used one and was it any good?

Unless it's good enough to stop my swarf-pickup problem I may have to try a DIY solution with an old transformer and a hacksaw(?*****)

Image from Farnell Website