SUMMARY

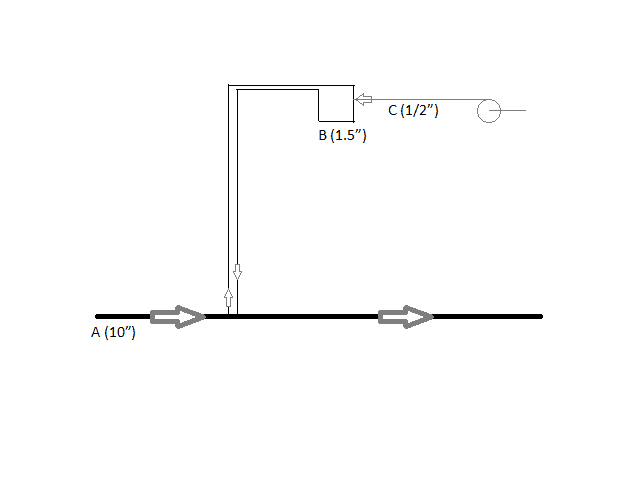

The discussion centers on optimizing chemical injection for viscous polymer during winter conditions, specifically addressing challenges with pumping polymer through a 1.5" line connected to a 10" water header. Participants concluded that installing heat tracing and insulation around the polymer pump is essential to maintain fluidity, as the polymer becomes too viscous in cold temperatures. Additionally, the use of an orifice or control valve to manage pressure and flow was debated, with concerns about potential head loss and its impact on downstream processes. Ultimately, the recommendation is to ensure proper heat tape installation and pump specifications to accommodate viscosity changes.

PREREQUISITES

- Understanding of polymer viscosity and its impact on flow

- Familiarity with heat tracing and insulation techniques

- Knowledge of fluid dynamics, particularly pressure loss in piping systems

- Experience with pump selection and specifications for varying viscosities

NEXT STEPS

- Research effective heat tracing systems for chemical applications

- Learn about orifice sizing and its effects on fluid dynamics

- Investigate pump technologies suitable for high-viscosity fluids

- Study insulation materials and installation techniques for piping systems

USEFUL FOR

Chemical engineers, facility managers, and maintenance personnel involved in polymer processing and chemical injection systems, particularly in cold weather environments.