Dafe

- 144

- 0

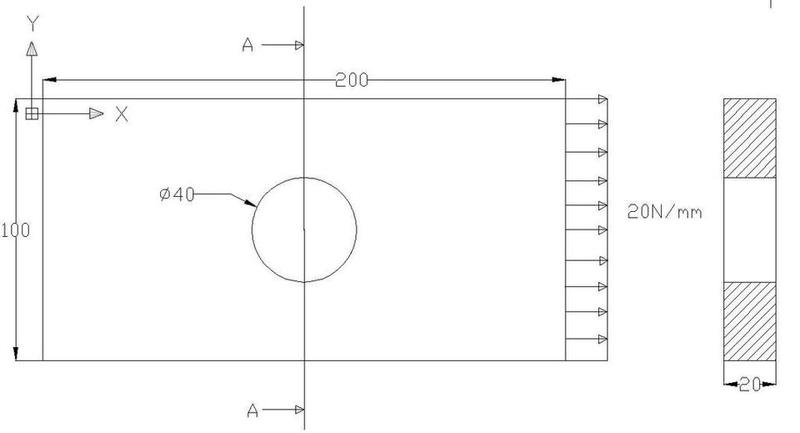

Hey, I'm trying to solve a little mechanics problem and I'm stuck.

I want to find the maximum stress in the system. I know that it should be at the top and bottom of the hole. The plate is fully constrained at the left edge.

I find the average tensile stress in section A:

sigma = F/A = 2000N/(100-40)*2 = 1,67N/mm^2

I also know that the stress distribution in section A is not even.

Could someone give me a little hint?

Thanks

I want to find the maximum stress in the system. I know that it should be at the top and bottom of the hole. The plate is fully constrained at the left edge.

I find the average tensile stress in section A:

sigma = F/A = 2000N/(100-40)*2 = 1,67N/mm^2

I also know that the stress distribution in section A is not even.

Could someone give me a little hint?

Thanks