SUMMARY

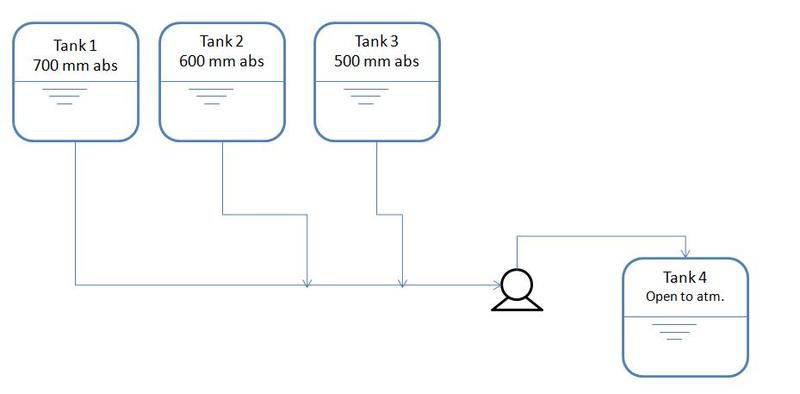

Pumping water from three vacuum tanks at different vacuum levels into a single atmospheric tank using a common pump and suction header is feasible, provided proper design considerations are implemented. The tanks, elevated 10 feet above the atmospheric tank, can achieve a flow rate of approximately 500 Litres/hr each through a 1/2 inch line. Check valves are recommended on the exit lines to prevent backflow and ensure system stability. If vacuum levels are stronger and none of the tanks are self-draining, the pumping scheme remains viable, but careful management of pressure differentials is essential to avoid cross-contamination.

PREREQUISITES

- Understanding of vacuum systems and pressure differentials

- Familiarity with fluid dynamics and flow rates

- Knowledge of piping design and sizing

- Experience with check valve applications in fluid systems

NEXT STEPS

- Research vacuum pump selection criteria for multi-tank systems

- Learn about fluid dynamics principles related to pressure profiles in piping

- Study the effects of check valves on flow and backflow prevention

- Explore advanced pumping strategies for varying vacuum levels

USEFUL FOR

Engineers, fluid mechanics specialists, and system designers involved in vacuum systems and fluid transport applications will benefit from this discussion.