argeus

- 2

- 0

- TL;DR

- pumping power calculation of a vertical closed-loop system assuming the hydrostatic term

Hi there,

I hope that somebody can help me with this.. Any response is much appreciated!

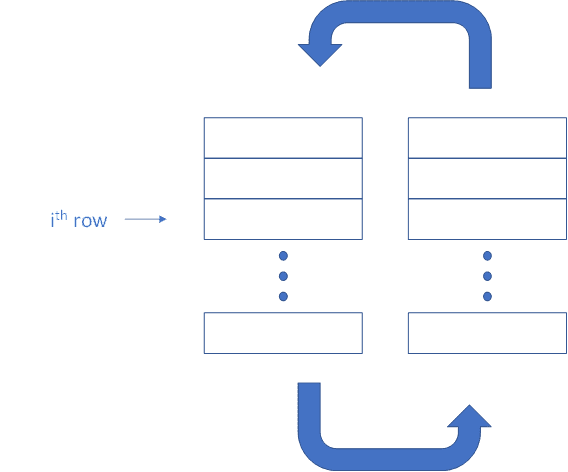

Let's have a vertical closed-loop system where the fluid circulates using the pump. The temperature in both sections gradually changes (the upcomer section is heated up) so that the densities, velocities, and pressure drop change as well. Hence, it would be beneficial to split the geometry into horizontal sections; each section (downcomer and upcomer) is divided into a certain number of elements, each of the same height. The point is to calculate the pumping power needed for fluid circulation. The total power is calculated per partes, i.e. for each ith row separately and then simply summed together.

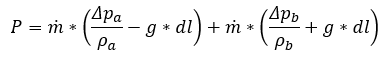

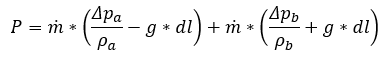

For any single ith row, the pumping power equation (w/o hydrostatic term) yields:

Note that subscript a refers to a downcomer and subscript b to an upcomer, respectively. Symbol m refers to the mass flow rate, ρ is density and Δp is the pressure drop across the element in the ith row as per Darcy friction eq.

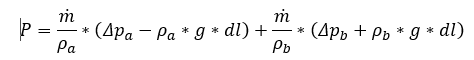

Now assuming a hydrostatic pressure due to the changing density, one gets:

Simply, g denotes gravitational acceleration, and the term dl refers to the height of the element in the ith row.

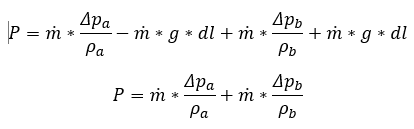

Rearranging a bit:

Since the mass flow is the same in both channels, we finally get:

Does this mean that the pumping power is independent of the hydrostatic pressure in the closed loop even when the fluid densities in both vertical channels differ? This does not seems correct to me, however, simply cannot find where I'm going wrong..

I hope that somebody can help me with this.. Any response is much appreciated!

Let's have a vertical closed-loop system where the fluid circulates using the pump. The temperature in both sections gradually changes (the upcomer section is heated up) so that the densities, velocities, and pressure drop change as well. Hence, it would be beneficial to split the geometry into horizontal sections; each section (downcomer and upcomer) is divided into a certain number of elements, each of the same height. The point is to calculate the pumping power needed for fluid circulation. The total power is calculated per partes, i.e. for each ith row separately and then simply summed together.

For any single ith row, the pumping power equation (w/o hydrostatic term) yields:

Note that subscript a refers to a downcomer and subscript b to an upcomer, respectively. Symbol m refers to the mass flow rate, ρ is density and Δp is the pressure drop across the element in the ith row as per Darcy friction eq.

Now assuming a hydrostatic pressure due to the changing density, one gets:

Simply, g denotes gravitational acceleration, and the term dl refers to the height of the element in the ith row.

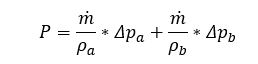

Rearranging a bit:

Since the mass flow is the same in both channels, we finally get:

Does this mean that the pumping power is independent of the hydrostatic pressure in the closed loop even when the fluid densities in both vertical channels differ? This does not seems correct to me, however, simply cannot find where I'm going wrong..

Attachments

Last edited: