Discussion Overview

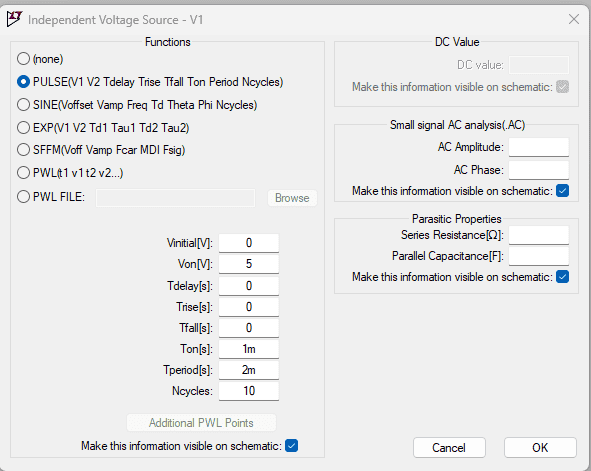

The discussion revolves around simulating a PWM (Pulse Width Modulation) signal with varying duty cycles from 0% to 100% in LTSpice, focusing on the behavior of inductor current as the PWM duty changes. Participants explore various aspects of PWM signal generation, its effects on inductor current, and the implications for circuit design.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

- Mathematical reasoning

Main Points Raised

- Some participants inquire about the specific variables to plot as a function of duty cycle, with a focus on inductor current.

- One participant suggests using a .PARAMeterise and .STEP commands in LTSpice to sweep through duty cycle values and measure average current.

- Another participant expresses a desire to generate a sine output current across an inductor by varying the PWM duty, raising questions about the frequency of the sine wave and PWM.

- Concerns are raised about the DC offset in the PWM signal and its effect on inductor current, with suggestions for alternative approaches to achieve a sinusoidal reference.

- Participants discuss the relationship between PWM duty cycle and average current through an inductor, noting the importance of averaging over a full cycle.

- There is a mention of the differences in behavior between capacitors and inductors when subjected to PWM signals, emphasizing the need for context in simulations.

- One participant provides detailed insights on the expected behavior of inductor current under PWM, including the effects of duty cycle on ripple current and DC components.

Areas of Agreement / Disagreement

Participants express a variety of viewpoints regarding the simulation of PWM signals and their effects on inductor current. There is no clear consensus on the best approach to achieve the desired sine output current, and multiple competing ideas and concerns are present throughout the discussion.

Contextual Notes

Participants highlight the importance of assumptions regarding signal types (unipolar vs. bipolar), the impact of duty cycle on current behavior, and the need to consider ripple and DC components in their analyses. Some mathematical steps and definitions remain unresolved, contributing to the complexity of the discussion.

Who May Find This Useful

This discussion may be useful for individuals interested in PWM signal generation, inductor behavior in circuits, and simulation techniques in LTSpice, particularly those exploring the nuances of duty cycle effects on current waveforms.