kapkichi

- 2

- 2

- TL;DR

- want to understand the mechanics/critical points of picking up a windmill tower with a crane.

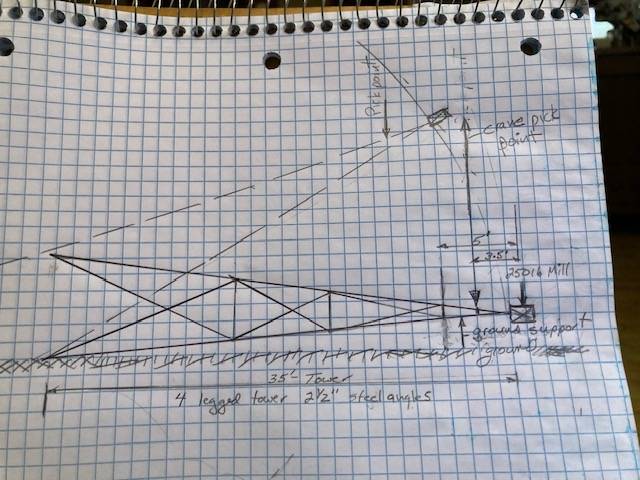

I have a retirement project in restoring an old farm windmill and am close to being ready for the install. I want to pick the 35' tower and mill head together in one operation using a crane. My last statics class was 45 years ago so I'm a little rusty. I know the mill weight of 250 lbs will add stresses during the lift that the tower wasn't designed for. The tower is about 700 lbs. I believe my concerns are the moment introduced by the mill in the horizontal position and the combined axial/bending stress on the 2 lower tower legs while it is being tipped up to vertical. My thought was to pick the tower 3.5' down from the top which is the bearing for the mill post. I can't lift from the mill head because it only sits in the tower by gravity.

My questions

Does my pick point limit the moment arm to 3.5 feet or should I be looking at the point where the first girt and tension diagonals are, 5' down from the top.

Is the horizontal position the worst case scenario for moment or somewhere else along the 90 degree rotation to vertical.

I'm thinking by using a crane (vs. jib beam and winch technique) with the pick point always vertical that should lessen the axial forces in the lower tower legs. Is 45 degrees the worst case for this. What would a FBD look like to analyze that? The original design doesn't have horizontal girts around the bottom. I have added those on all 4 faces to help distribute the lower tower leg load to all 4 legs. Once the tower is hanging vertical I will attach leg anchors and socket into bored holes. one of the windmill forums offered some ancedotal advice suggesting the lower legs be lifted while the crane is picking to vertical (could due that with tractor on the lower girt) but I fail to see the value in doing that. I have attached a sketch to help visualize

Any advice, sketches of a FBD on how to further analyze would be welcome

My questions

Does my pick point limit the moment arm to 3.5 feet or should I be looking at the point where the first girt and tension diagonals are, 5' down from the top.

Is the horizontal position the worst case scenario for moment or somewhere else along the 90 degree rotation to vertical.

I'm thinking by using a crane (vs. jib beam and winch technique) with the pick point always vertical that should lessen the axial forces in the lower tower legs. Is 45 degrees the worst case for this. What would a FBD look like to analyze that? The original design doesn't have horizontal girts around the bottom. I have added those on all 4 faces to help distribute the lower tower leg load to all 4 legs. Once the tower is hanging vertical I will attach leg anchors and socket into bored holes. one of the windmill forums offered some ancedotal advice suggesting the lower legs be lifted while the crane is picking to vertical (could due that with tractor on the lower girt) but I fail to see the value in doing that. I have attached a sketch to help visualize

Any advice, sketches of a FBD on how to further analyze would be welcome

Last edited by a moderator: