Plu3m

- 3

- 0

Hi there, I'm new to this forum and this is my first post so nice to meet you all!

Since English is my second language, I apologize for some odd sentences.

I'm a 4th year university student and currently has an internship in a Press Shop of a car manufacturer in Thailand. The project has been given to me by the training staff to find a solution for quality problems in a specific part stamping operation due to the reason stated below.

For a quality problem, a specific part has die marks (a scratch caused by lower die setting is not in a right position when upper die is stamping). A cause of the problem is two pneumatic cylinders installed in the lower die(in order to set the die in the right shape prepare for stamping) are not supplied by proper amount of compressed air within the set timing(in short, like pneumatic need to complete its cycle within 5 seconds for the lower die to set in a right shape, but right now the pneumatic spend like 10 seconds per cycle).

My solution for the problem is to redesign pipeline, valves or add an air tank to the line. This idea is coming up because when I calculated the air flow rate using the current pipe size a result shows that compressed air flow is not sufficient for the current operation.

The question is "How do I know that my calculation steps utilized are proper?" so I'm here to ask experts!

Given Specs: Bore diameter 250mm , Stroke 200mm, Rod diameter 60mm , operate at 5 bar at STP.

The cylinder is a Double-Acting type with required Extend Stroke 1.177 sec and Retract Stroke 2.200 sec.

These are the steps how I design for air consumption, required flow rate and pipe/valve sizing.

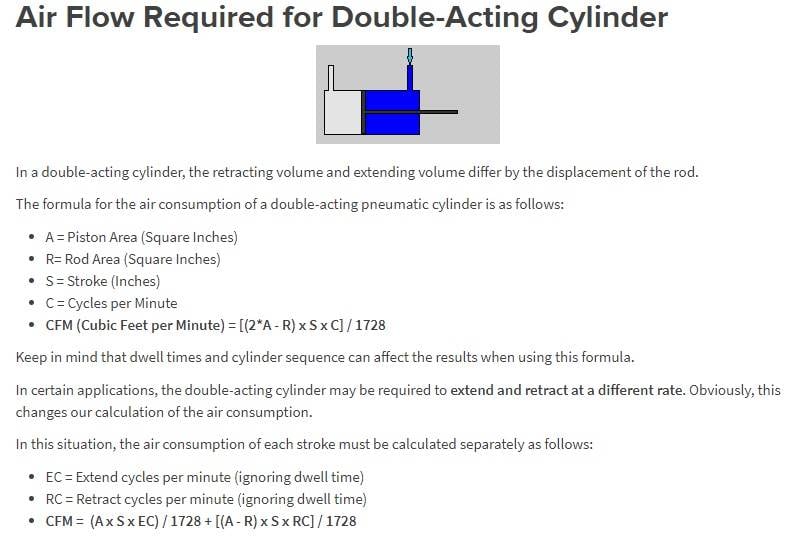

1. Calculate pneumatic air consumption in SCFM (SCFMtotal = SCFMextend + SCFMretract)

Source: https://cross-automation.com/blog/pneumatic-cylinder-air-flow-requirements

2. Calculate Flow Coefficient(Cv) to select a proper valve size.

Source: http://www.globalspec.com/pfdetail/valves/flow

3. Pipe Sizing and system specs (pipe size, length, fitting) by using SCFMtotal obtained from (1.) to select a proper Pipe Size and effective length.

Source: Parker Pneumatic

Here's some additional questions:

Do the calculation steps above sufficient enough to design for the system?

Is an air tank needed in the system, what is its profit?

Is there any improper calculation steps above, I'm waiting for your advice!

Thanks in advance! and nice to meet you all again.

Since English is my second language, I apologize for some odd sentences.

I'm a 4th year university student and currently has an internship in a Press Shop of a car manufacturer in Thailand. The project has been given to me by the training staff to find a solution for quality problems in a specific part stamping operation due to the reason stated below.

For a quality problem, a specific part has die marks (a scratch caused by lower die setting is not in a right position when upper die is stamping). A cause of the problem is two pneumatic cylinders installed in the lower die(in order to set the die in the right shape prepare for stamping) are not supplied by proper amount of compressed air within the set timing(in short, like pneumatic need to complete its cycle within 5 seconds for the lower die to set in a right shape, but right now the pneumatic spend like 10 seconds per cycle).

My solution for the problem is to redesign pipeline, valves or add an air tank to the line. This idea is coming up because when I calculated the air flow rate using the current pipe size a result shows that compressed air flow is not sufficient for the current operation.

The question is "How do I know that my calculation steps utilized are proper?" so I'm here to ask experts!

Given Specs: Bore diameter 250mm , Stroke 200mm, Rod diameter 60mm , operate at 5 bar at STP.

The cylinder is a Double-Acting type with required Extend Stroke 1.177 sec and Retract Stroke 2.200 sec.

These are the steps how I design for air consumption, required flow rate and pipe/valve sizing.

1. Calculate pneumatic air consumption in SCFM (SCFMtotal = SCFMextend + SCFMretract)

Source: https://cross-automation.com/blog/pneumatic-cylinder-air-flow-requirements

2. Calculate Flow Coefficient(Cv) to select a proper valve size.

Source: http://www.globalspec.com/pfdetail/valves/flow

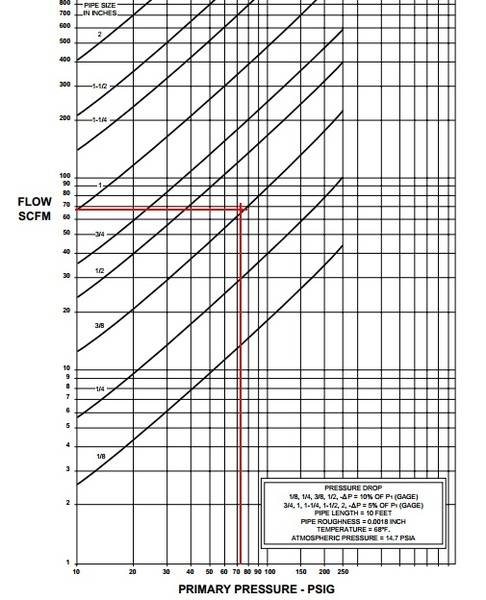

3. Pipe Sizing and system specs (pipe size, length, fitting) by using SCFMtotal obtained from (1.) to select a proper Pipe Size and effective length.

Source: Parker Pneumatic

Here's some additional questions:

Do the calculation steps above sufficient enough to design for the system?

Is an air tank needed in the system, what is its profit?

Is there any improper calculation steps above, I'm waiting for your advice!

Thanks in advance! and nice to meet you all again.

Last edited: