- #1

Saladsamurai

- 3,020

- 7

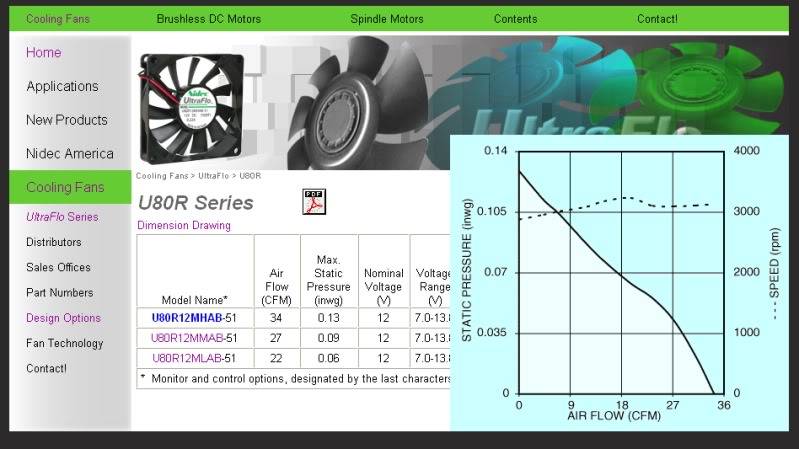

I am looking at fan curves here at work and I stumbled upon this one. Its for an 80mm diameter tube axial fan.

What's up with the Flowrate vs RPM curve (the dashed line)?

In the flowrate interval between 12 - 23 CFM there are instances of the same RPM for different flowrates.

That doesn't make sense to me For a fixed geometry and a fixed RPM how on Earth can we have different flowrates?

For a fixed geometry and a fixed RPM how on Earth can we have different flowrates?

Unless it is accounting for blade deformation?

Any thoughts?

What's up with the Flowrate vs RPM curve (the dashed line)?

In the flowrate interval between 12 - 23 CFM there are instances of the same RPM for different flowrates.

That doesn't make sense to me

Unless it is accounting for blade deformation?

Any thoughts?