Owen Ransen

- 7

- 1

- TL;DR

- How to interpret torque claims for servo motors which seem to me to be ridiculous.

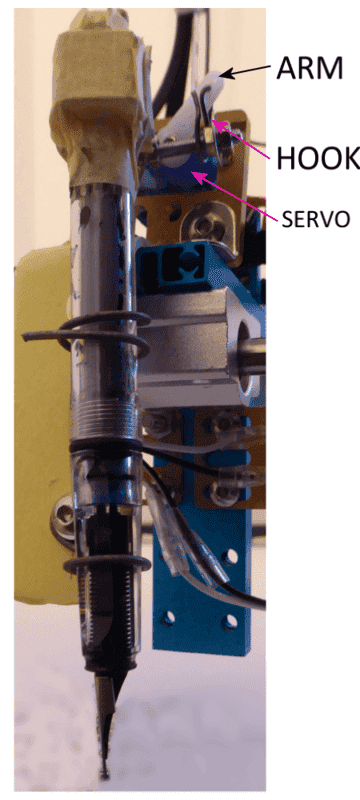

I'm using a servo to lift a pen. The pen and a bit of mechanism weights 35g.

The servo I use to bring the pen up and down claims to have a torsional moment of 1.5kg/cm. Sometimes they call it torque in the specs. But surely that does not mean they are claiming that if I hung a 1.5kg weight a 1 centimeter arm then the servo would be able to move?

The tiny 9g servo is shown here:

https://www.amazon.com/dp/B01MXPTCHO/?tag=pfamazon01-20

My servos fail a lot (die) and I'm asking because I've been told that the pen is too heavy for the servo. But if the servo can do 1.5kg.cm sure it can do 0.035*2 kg.cm? What am I missing?

(I realize it should be in Newtons per meter, but servos seem to always be specified in kg.cm (or oz.in even!).)

The servo I use to bring the pen up and down claims to have a torsional moment of 1.5kg/cm. Sometimes they call it torque in the specs. But surely that does not mean they are claiming that if I hung a 1.5kg weight a 1 centimeter arm then the servo would be able to move?

The tiny 9g servo is shown here:

https://www.amazon.com/dp/B01MXPTCHO/?tag=pfamazon01-20

My servos fail a lot (die) and I'm asking because I've been told that the pen is too heavy for the servo. But if the servo can do 1.5kg.cm sure it can do 0.035*2 kg.cm? What am I missing?

(I realize it should be in Newtons per meter, but servos seem to always be specified in kg.cm (or oz.in even!).)