davidwinth

- 103

- 8

- TL;DR

- I am trying to understand both why a horizontal shear is shown in the flange of a beam with a vertical load and how the directions are defined.

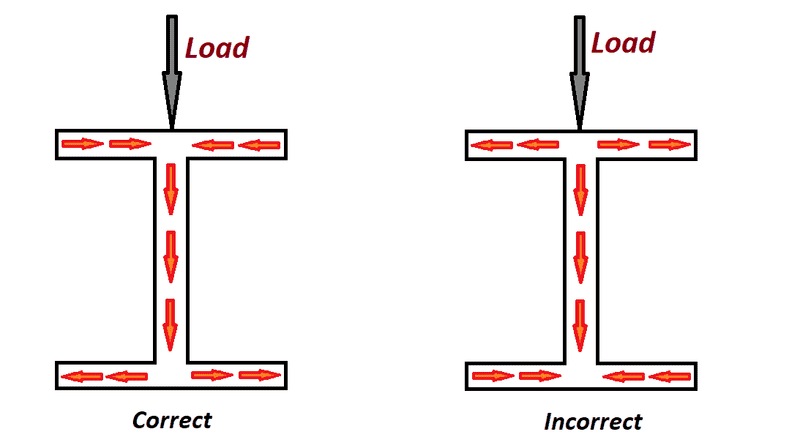

In an I-beam, the shear flow is usually shown drawn as on the left, not as drawn on the right. I do not understand why. I do understand:

It matters because, when accounting for the direct shear due to an additional horizontal force (pushing to the right), we will subtract the shears on the upper right hand side of the left I-beam to get the net. If we were to use the right I-beam, we'd have to add the shears to get the net. So the net shear said to exist in the upper right flange of the I-beam depends vitally on the direction assigned to the shear flow, and yet I see no physical reason to favor of one or the other convention.

1. How can I understand why a vertical force produces horizontal (left/right) shear and

2. Why the direction is chosen as it is?

- The total horizontal shear force must be zero, consistent with statics.This is satisfied in both images.

- The vertical direction matches the direction of the external load.

- There is a longitudinal horizontal shear (in to or out of the plane of the cross section). That, I understand.

It matters because, when accounting for the direct shear due to an additional horizontal force (pushing to the right), we will subtract the shears on the upper right hand side of the left I-beam to get the net. If we were to use the right I-beam, we'd have to add the shears to get the net. So the net shear said to exist in the upper right flange of the I-beam depends vitally on the direction assigned to the shear flow, and yet I see no physical reason to favor of one or the other convention.

1. How can I understand why a vertical force produces horizontal (left/right) shear and

2. Why the direction is chosen as it is?

Last edited: