Metallus

Hello,

I'm carrying out electrical resistivity tests with the Van der Pauw method on a round sample (2 mm thick disk) of a doped ceramic but sometimes I have issues in the mounting of the sample.

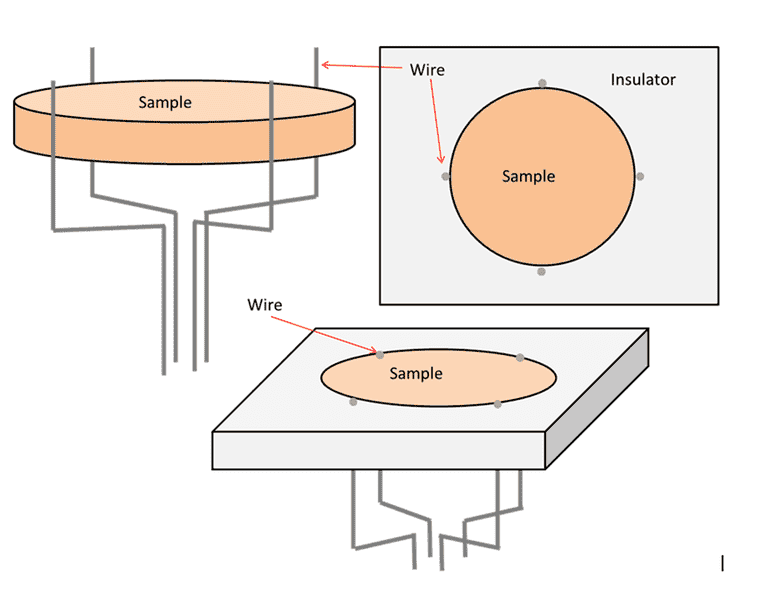

I'm using a 4-probe tube where each of the 4 wires contacts with the "corners" of the sample. To keep everything together, the sample is mounted on a sample holder made of insulation material that keeps the wire in contact with it. Here's a pic of the set-up, profile view and top view

Sometimes when I attempt to pass current in any of the 8 configurations (reciprocal measurements and polarity inversion measurements), I get infinite resistivity. Is it due to the wires not being perfectly in contact with the sample? Why does it work in some configuration but give infinite resistivity in the other? And why sometimes the signal remains 0? Does it mean that it's short circuiting somewhere (as if the wires were touching)?

What am I doing wrong exactly? I made it work before, so I guess I'm just screwing up in the preparation of the sample somewhere, but I don't know where exactly, nor I know what could be the source of error. Let me know if you need additional details, as I am new to this technique.

Thanks

I'm carrying out electrical resistivity tests with the Van der Pauw method on a round sample (2 mm thick disk) of a doped ceramic but sometimes I have issues in the mounting of the sample.

I'm using a 4-probe tube where each of the 4 wires contacts with the "corners" of the sample. To keep everything together, the sample is mounted on a sample holder made of insulation material that keeps the wire in contact with it. Here's a pic of the set-up, profile view and top view

Sometimes when I attempt to pass current in any of the 8 configurations (reciprocal measurements and polarity inversion measurements), I get infinite resistivity. Is it due to the wires not being perfectly in contact with the sample? Why does it work in some configuration but give infinite resistivity in the other? And why sometimes the signal remains 0? Does it mean that it's short circuiting somewhere (as if the wires were touching)?

What am I doing wrong exactly? I made it work before, so I guess I'm just screwing up in the preparation of the sample somewhere, but I don't know where exactly, nor I know what could be the source of error. Let me know if you need additional details, as I am new to this technique.

Thanks